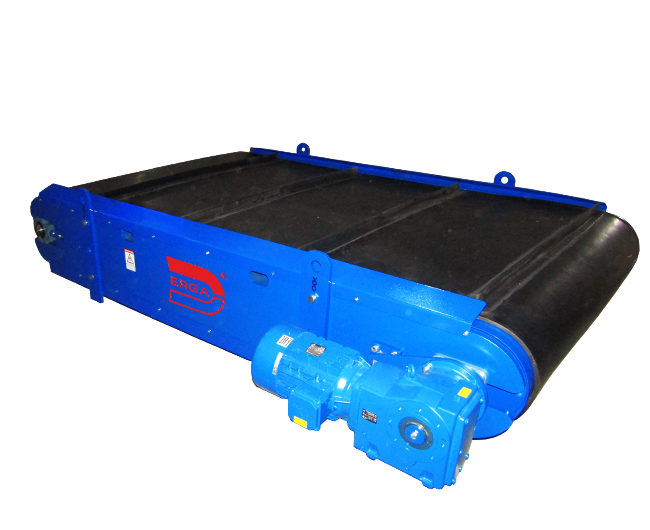

ERGA TS trommel screen

ERGA TS trommel screen for sizing various lump and bulk materials

-

High degree of cleaning

-

Efficient screening into 3 fractions

-

Additional automatic cleaning

-

Easy assembly and operation

-

Wide range of options and settings

-

Efficient operation 24/7 in harsh conditions

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Industries

ERGA TS trommel screen (drum screen, tumbling drum, rotary screening machine) is used for sorting bulk materials in construction, mining, wood processing and utilities industries, as well as in recycling, as part of process lines or crushing and screening plants.

- High degree of cleaning

The advantage of ERGA TS trommel screen is high degree of cleaning the infeed product with a wide range of sizes.

- Efficient screening into 3 fractions

ERGA TS screens efficiently operate with clumpy, sticky and cloggy materials. Trommel screens have adjustable inclination angle for optimum material separation and advancement of a coarser fraction to discharge end. They are equipped with screens of various designs and from perforated steel sheets with required mesh sizes and shapes. If it is necessary to classify material into several fractions, ERGA TS screens will consist of several screening sections with different mesh sizes. Depending on material, the screens can be with square, round, slotted or non-standard mesh.

- Additional automatic cleaning

The design of the drum screen provides for the installation of cleaning brush, rotating on the outer side of the trommel to clean the screen holes in case of clogging with fine material.

- Easy installation and operation

Simple and robust design of ERGA TS screening machine with minimum installation time and maintenance costs ensures high degree of screening efficiency for a wide variety of dry and wet materials from compost to coal or slags. Remote control of the screen operation makes control and operation settings easier. Operating parts made of wear-resistant high-strength materials increase life, replacement of the trommel or its sections is easy.

- Wide range of options and settings

The screen with rotating screen surface can be enclosed or open design, it is optionally equipped with an infeed hopper, a grate preventing large piece getting inside, (discharge) conveyors, and a service platform. For processing municipal and industrial waste the trommel can be equipped with special spikes for opening bags. A special infeed hopper can be installed for easy loading from different types of loaders.

- Efficient operation 24/7 in harsh conditions

The equipment is designed for both periodic and continuous operation, even in harsh conditions.

- Have difficulties choosing or haven’t found what you are looking for?

Contact us in any convenient way and we will select suitable solution for you.