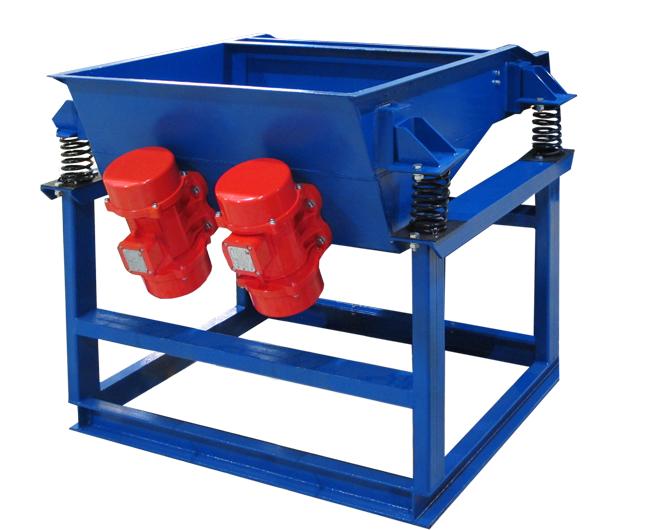

ERGA dosing hopper

ERGA dosing hopper for feeding bulk materials as part of processing complexes and lines

-

Bespoke design

-

Wide range of options and settings

-

Downtime minimization, no bagging

-

Easy installation and operation

-

Efficient operation 24/7 in harsh conditions

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Industries

ERGA infeed hoppers are used as part of complexes for sorting, conveying or dosing lumpy, powdery, granular materials, as well as part of ERGA process lines.

- Bespoke design

The volume and configuration of the hopper are selected considering the required capacity, loader volume and product particle size, taking into account the operation peculiarities. Research and Production Company “ERGA” manufacturers the following types:

- receiving hoppers designed for receiving bulk materials from vehicles (loaders and excavators);

- compensatory (damping) bunkers for balancing feed load on separate assemblies;

- dosing and storage hoppers (hopper system) for accumulation of material and its dosage prior to the process (mineral processing). Availability of dosing and storage hopper allows you to feed the product discharged from big bags.

- Wide range of options and settings

Material can be fed into the hopper from loader, crane or conveyor belt. The hoppers are equipped with vibratory feeders for uniform feed of material and various metering devices. Optional vibrating or hydraulically lifted grate is provided for separation of materials. If the material is prone to bridging or arching, there is an option to install a vibrator. Variable frequency drive provides adjustment of material flow rate to downstream equipment.

- Downtime minimization, no bagging

Reliable material feed from the hopper ensures continuous line operation without downtimes. The hopper can be equipped with the bulk material level sensor to guarantee stable operation and protect downstream components of the line.

- Easy installation and operation

Smart and robust design of the hopper makes it an irreplaceable part of numerous ERGA installations. Wear parts are lined with wear-resistant plates. Depending on specifics of the production the hoppers are made of stainless or carbon steel.

- Have difficulties choosing or haven’t found what you are looking for?

Contact us in any convenient way and we will select suitable solution for you.