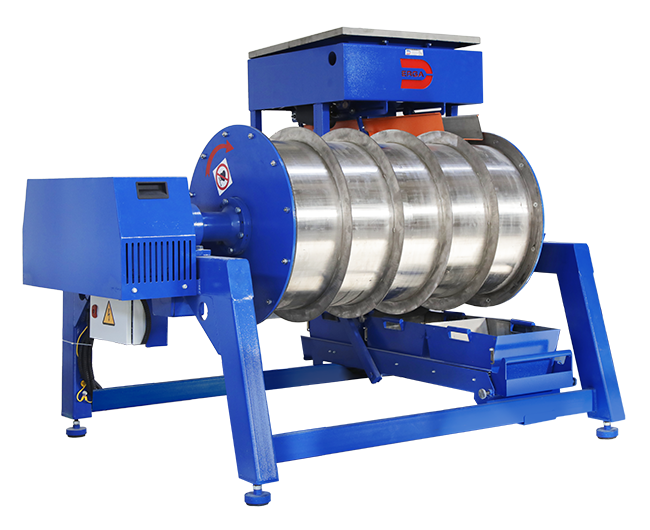

Laboratory magnetic drum separator ERGA DrumMag

Laboratory magnetic drum separator for dry concentration of strongly and feebly magnetic ore and nonmetallic materials

-

Magnetic system with intensity from 50 to 900 mТ (500 – 9 000 Gauss)

-

Wide range of separation settings

-

Customized selection of equipment

-

Automatic cleaning

-

Operation with abrasive materials

-

Compact and mobile

-

Easy to operate and maintain

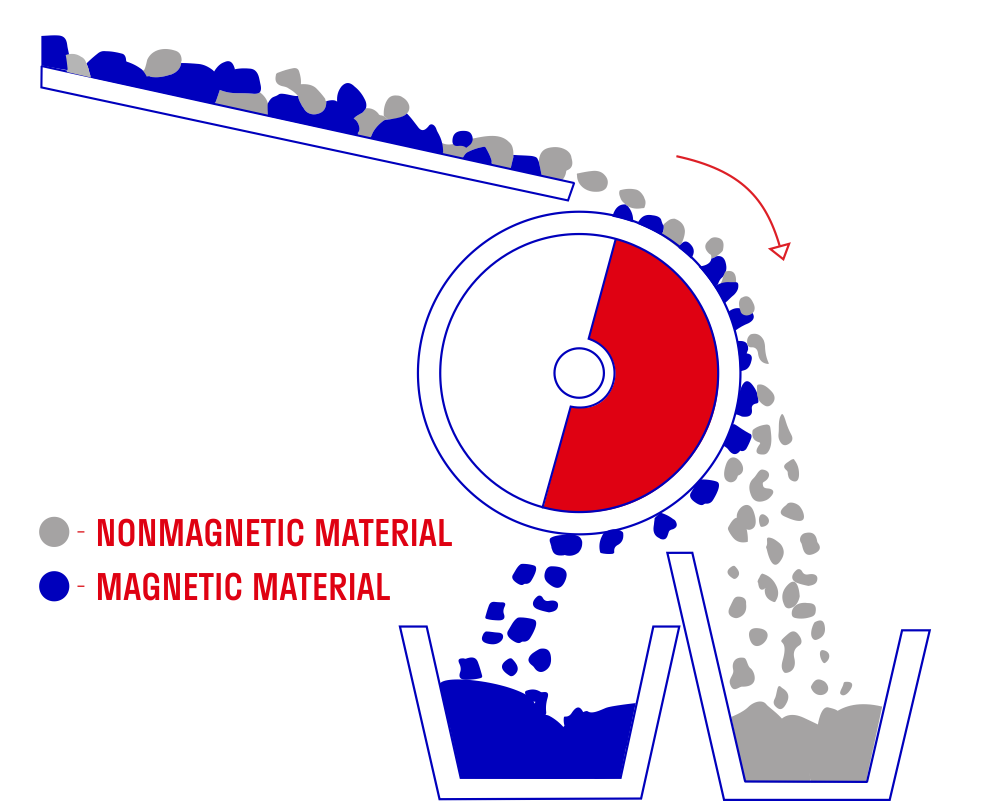

Operation Principle

Industries

Modification of ERGA DrumMag magnetic drum separator for studying applicability of technological processes for beneficiation of ores and slags, bulk food products, recovery of rough concentrates and conducting scientific research in industrial and university laboratories.

- Magnetic system with intensity from 50 to 900 mТ (500 – 9 000 Gauss)

The drum magnetic field intensity value determines its efficiency for removal of metal inclusions. For separation of materials with different magnetic susceptibility it is possible to manufacture special magnetic system with magnetic intensity adjustment from 50 to 900 mT (from 500 to 9,000 Gs) on the drum shell surface.

- Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic with minimum personnel involvement.

Continuous removal of magnetic inclusions in automatic mode improves separation quality compared to separators with mechanical or manual cleaning (ERGA PlateMag 2). Special design of ribs minimizes material carryover into the magnetic fraction.

- Customized selection of equipment

ERGA DrumMag laboratory magnetic separator is optimized for application in different operating modes: continuous or periodic. The drum diameter can vary from 150 to 600 mm, depending on material sizes (effective recovery of magnetic inclusions from 180 mm to 0.02 mm). The drum length is selected taking into account the design capacity.

- Compact and mobile

The use of permanent magnets in the separator ensures its low power consumption. BSM-L is distinct in compactness, easy maneuverability and convenient use in laboratory conditions.

- Wide range of separation settings

The drum speed can be adjusted with a frequency converter, the presence of infeed hopper with a slide gate and a vibrating feeder in its design allows for adjustment of the process capacity and ensures monolayer material feed, fine setting of splitter provides accurate separation of fractions by magnetic properties.

- Operation with abrasive materials

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel. In case of operation in highly abrasive medium, the separator shell is additionally lined with wear plates.

- Easy to operate and maintain

Simple and robust design with little maintenance ensures easy operation of ERGA DrumMag laboratory separator. Drum shell is made of wear-resistant stainless steel.

The scope of supply of magnetic separators includes support frames (stationary or mobile configurations), infeed hoppers, vibrating chutes, variable speed drives, containers for products of separation, replaceable shells, etc.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA specialists manufacture various bespoke models of laboratory and pilot DrumMag magnetic separators.

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- shell

- bearings

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor