Eddy current magnetic separators ERGA EddyFlow and EddyFlow E

Eddy current magnetic separators for recovery of nonferrous metals from nonmagnetic materials

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal particles from 3 mm

-

User-friendly and fast setup

-

Highly efficient NdFeB magnetic system

-

Automatic operation in continuous mode

-

Low power consumption

-

Easy assembly and operation

-

Dry separation method

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

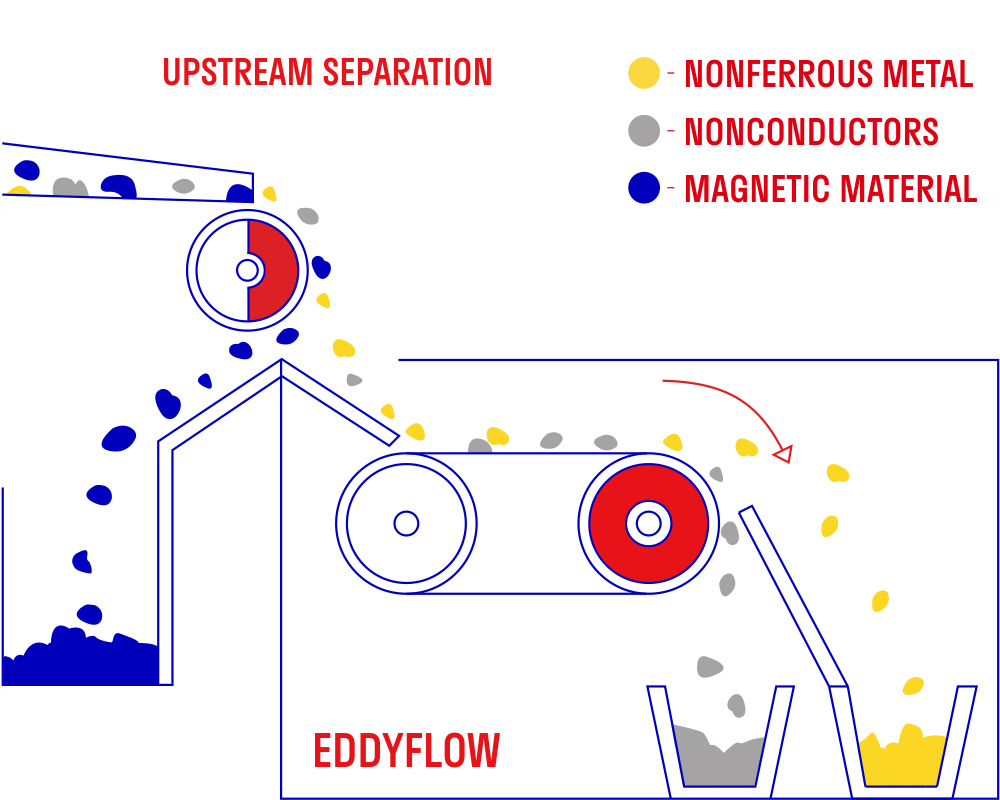

Operation Principle

Industries

ERGA EddyFlow and EddyFlow E current magnetic separators ensure recovery of nonferrous metals from nonconductive materials in processing of mixed municipal waste, shredded cable, plastics, WEEE, cullet, scrap, wood chips, incineration bottom ash, smelters’ nonferrous slags.

- Highly efficient NdFeB magnetic system

Depending on operation specifics and conditions eddy current separators are designed as EddyFlow E series with eccentric arrangement of magnetic rotor relative to the drum axis or as EddyFlow series with concentric rotor. Rotor configuration and the number of poles determine efficiency of extraction of nonferrous metal inclusions. Unique patented Nd-Fe-B magnetic systems provide long-term efficient operation of magnetic separators. Guaranteed period of magnetic systems properties, subject to operating rules, is 10 years

- Fine setting of separation mode

Capability to control conveyor belt speed and frequency of rotation of the magnetic rotor by means of frequency converters ensure quick setting of ERGA EddyFlow and EddyFlow E operation modes for maximum separation efficiency.

- Separation/cleaning efficiency up to 99,8%

Customized separation mode is selected depending on feed material. Precise adjustment of splitter position and magnetic rotor speed up to 3000 rpm help to achieve 99.8% of feed material separation and cleaning efficiency.

- Easy assembly and operation

Smart design provides quick belt change, protects the magnetic rotor from tramp metal under the belt, simple design of bearing assemblies increases reliability and also guarantees maintainability of the magnetic rotor, which reduces equipment downtime.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced ERGA EddyFlow and EddyFlow E eddy current separators are given in table. Customized solutions can be designed according to the order requirements. Strongly magnetic impurities must be removed from the separation materials by RGA SuspendMag M or SuspendMag A suspended iron separators, pulley iron separators ERGA PullMag or drum separators ERGA DrumMag prior to eddy current magnetic separators.

| Model | Dimensions, mm | Weight, kg | Power consumption, kW |

|---|---|---|---|

| EddyFlow VF 400 | 2920х1486х980 | 550 | 4 |

| EddyFlow VF 600 | 2920х1586х980 | 650 | 4,5 |

| EddyFlow VF 800 | 2920х1786х980 | 800 | 5,5 |

| EddyFlow VF 1000 | 2920х1986х980 | 1030 | 5,5 |

| EddyFlow VF 1200 | 2920х2186х980 | 1250 | 7 |

| EddyFlow VF 1500 | 2920х2486х980 | 1580 | 9 |

| EddyFlow VF 2000 | 4900х3100х1100 | 3850 | 15 |

| EddyFlow 400 + DrumMag VF 335х300 | 3200х1285х1400 | 840 | 4,5 |

| EddyFlow 600 + DrumMag VF 335х400 | 3500х1586х1400 | 1030 | 6 |

| EddyFlow 800 + DrumMag VF 335х600 | 3500х1786х1400 | 1100 | 8 |

| EddyFlow 1000 + DrumMag VF 335х800 | 3500х1986х1400 | 1250 | 8 |

| EddyFlow 1500 + DrumMag VF 335х1000 | 3500х 2486х1400 | 1650 | 12 |

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- belt

- bearings

- shell

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Splitter, flap position sensor

- Access to complete information about operation of the machine (operation / idle, operating modes, error decoding, position of magnetic rods, cleaning period)

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor