Metal detection - modern technology for detection and removal of metal from recycled plastic

- #Plastic recycling

- #Plastic waste recycling

- #Metal detectors

Due to poor quality of manual sorting of municipal solid waste, secondary plastic is often contaminated with ferrous and nonferrous metal inclusions. In this regard, plastic waste processing plants face problems of identifying and removal of metal impurities, which reduce the quality of raw materials and can lead to damage and downtime of crushing and grinding equipment.

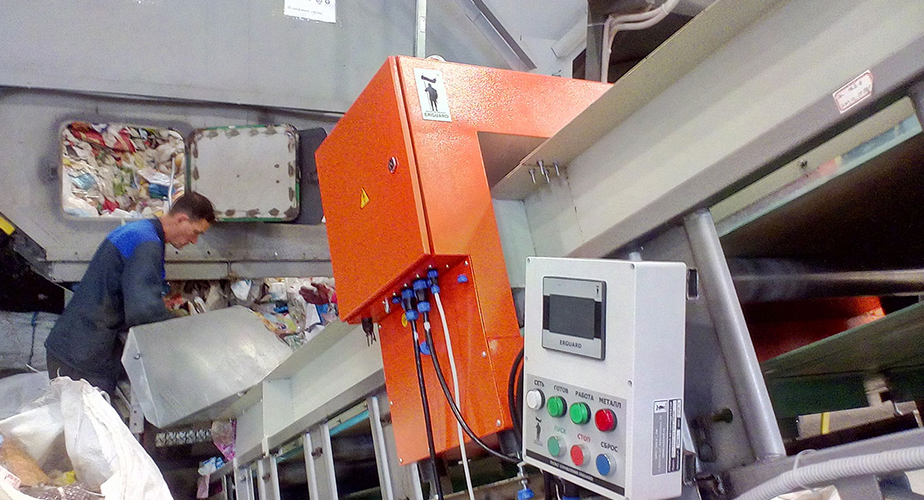

For example, conveyor metal detectors ERGUARD DCM and ERGUARD CM have proven effective in the recycling of PET bottles or waste of LDPE and HDPE films.

Fig. 1 ERGUARD DCM metal detector in plastic recycling line

Metal detector unit (MD) operation principle is based on change in magnetic flux generated by transmitting coil. When metal inclusion gets into the detection area, the magnetic flux changes, which is recorded by the receiving coil of MD unit.

Application of ERGUARD DCM and ERGUARD CM help customers to detect metal inclusions ≥1 mm in the raw materials in the form of parts of aluminum cans, lids, wire, bolts, nuts, including stainless steel.

Depending on Customer’s requirements ERGUARD metal detectors can be completed with custom designed hoppers, conveyors and rejection systems, taking into account the site of equipment installation. In addition, this equipment type has an option of integrating automated remote monitoring system REMOS, which monitors the equipment condition, transmitting data in real time.

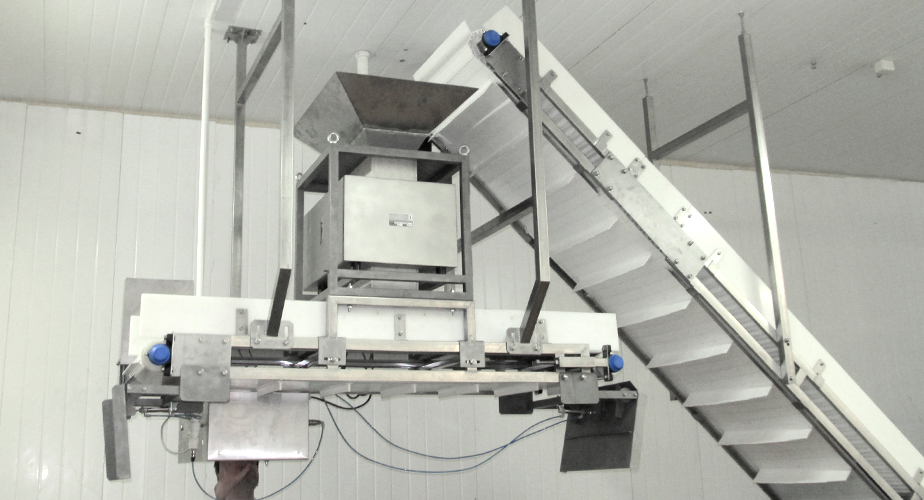

Fig. 2 ERGUARD GM metal detector with hopper, conveyor and rejection system

Reduced secondary polymers, such as PET bottles (PET-flakes) or PVC profiles, prior to shipment to the end consumer or receiving granules, have increased quality requirements, namely, to metal content. The most effective solution for PET cleaning is ERGUARD GM gravity metal detectors.

Fig. 3 ERGUARD GM metal detector as part of the line

Operation principle of ERGUARD GM gravity metal detector is similar to the principle of conveyor-type metal detectors. Distinctive features of GM series are free fall material detection, increased sensitivity and built-in automatic rejection system.

Fig. 4 Operation scheme of ERGUARD GM gravity metal detector

This type of metal detector detects and rejects metal particles from 0.8 mm, which protects expensive equipment (granulators, extruders, etc.) from breakdowns and downtime.

The use of modern technologies in recycling, in particular metal detection, ensures guaranteed equipment protection, process continuity and confidence in the quality of secondary raw materials to recycling companies.