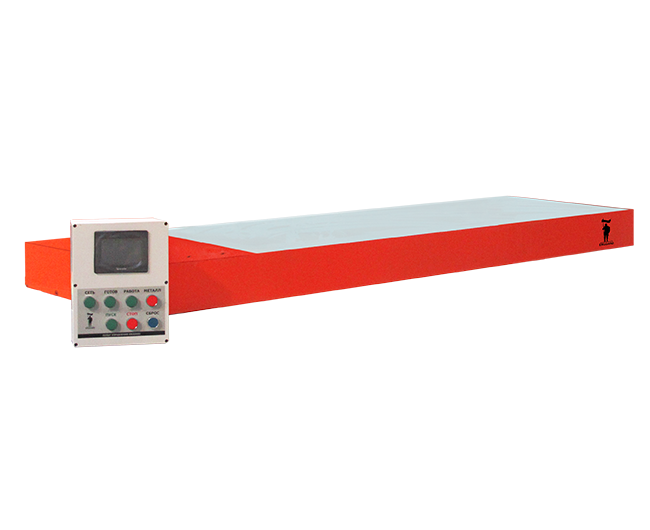

Overbelt magnetic separator ERGA SuspendMag М

Suspended magnetic separator with mechanical cleaing for removal of large metal inclusions from material flows transported by conveyors

-

Efficient recovery of large strongly magnetic impurities

-

Removal area depth up to 450 mm

-

Mass of recovered metal up to 40 kg

-

Easy assembly and operation

-

Easy cleaning

-

Protection of crusher, shredder from damage and early wear

-

No power consumption

-

Powerful permanent magnetic system

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

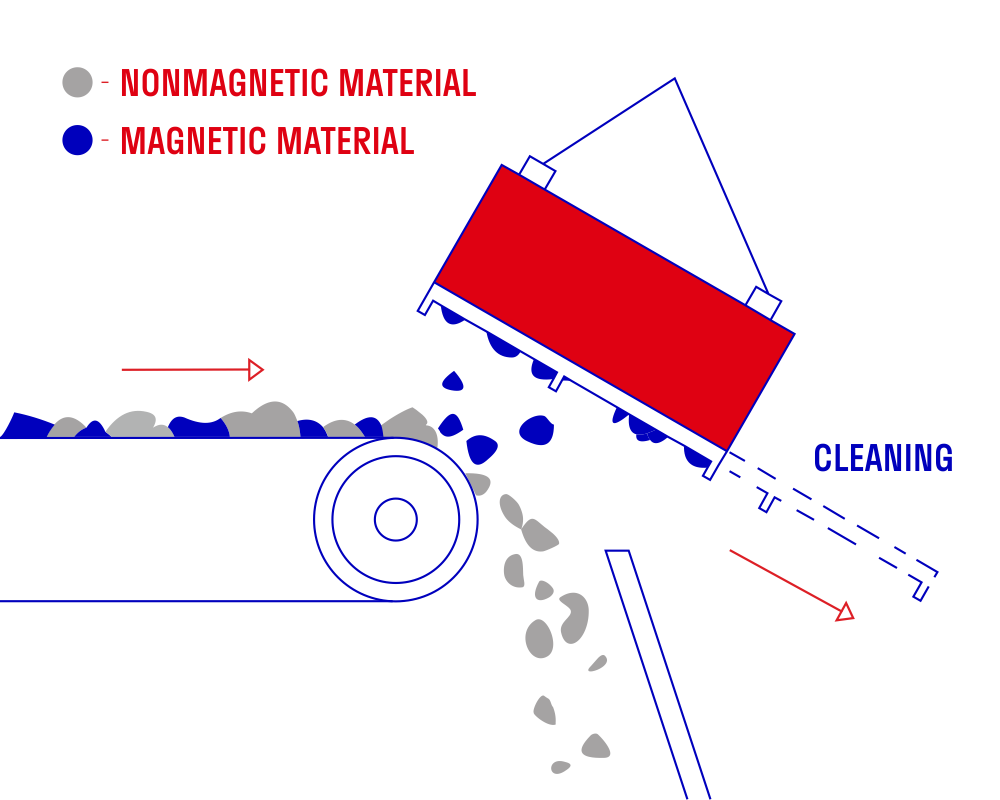

Operation Principle

Industries

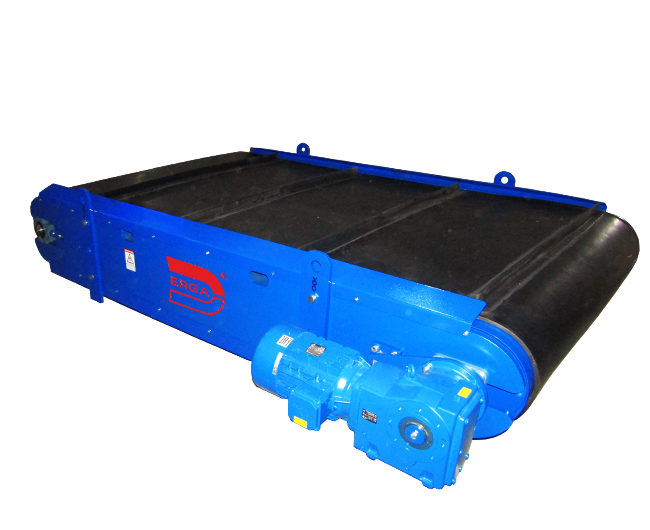

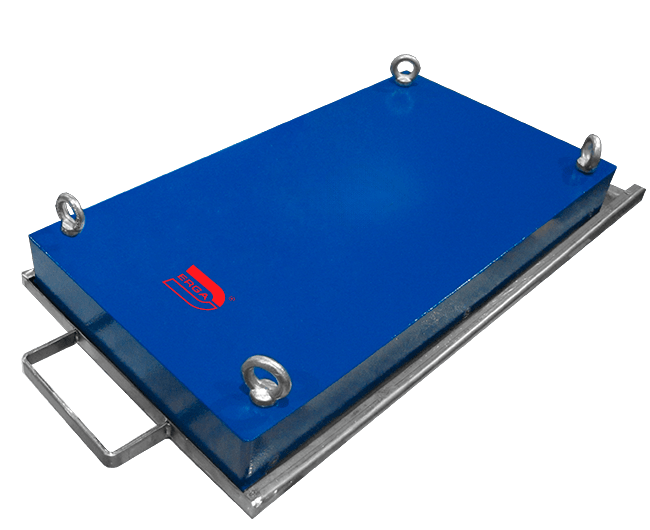

ERGA SuspendMag М overband magnetic separator with mechanical cleaning ensures quality removal of large strongly magnetic inclusions with mass up to 40 kg from material flow from distance up to 450 mm.

- Efficient recovery of large strongly magnetic impurities

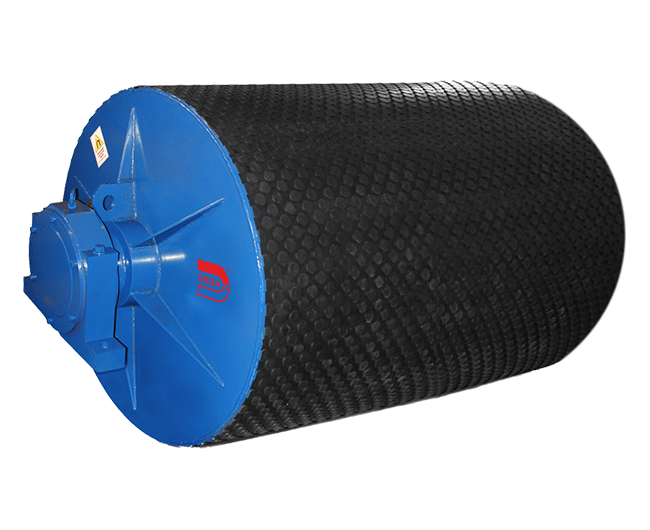

ERGA SuspendMag М overbelt magnetic separator has powerful permanent magnetic system, ensuring maximum removal depth up to 450 mm for strongly magnetic inclusions. SuspendMag М is especially effective when applied for material with moderate contents of large strongly magnetic inclusions weighing up to 40 kg. In case of high content of metal impurities, we recommend using ERGA SuspendMag A suspended self-cleaning magnetic iron separator.

- Protection of crusher, shredder from damage and early wear

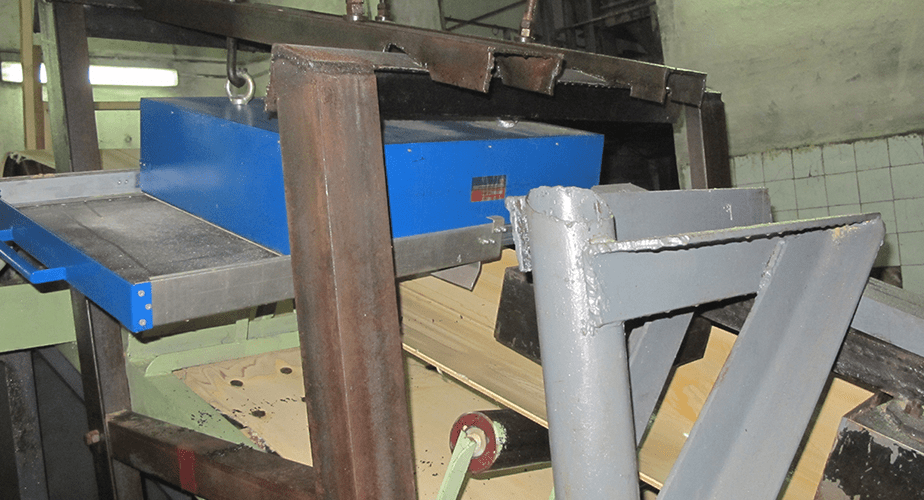

The magnetic separator is installed over conveyor or at discharge from the conveyor belt. Simple in appearance SuspendMag М design with powerful magnetic system inside prevents damage to crusher or shredder with all the resulting financial losses.

- No power consumption

ERGA SuspendMag М magnetic separator does not consume any electric power for magnetic field generation and differs from electromagnetic analogs in significantly greater reliability. The guaranteed shelf life of the properties of the magnetic system, subject to operating rules, is 10 years.

- Easy assembly and operation

ERGA SuspendMag М overbelt magnetic separator is integrated into existing process line and does not require any considerable redesign of the installation site.

Easy in maintenance, SuspendMag М operates without any additional settings, lubrication and close attention from the personnel.

- Easy cleaning

The magnetic separator has moving ribs making mechanical cleaning easier: it is enough to push the rib out of the magnetic field and metal impurities fall off.

- Conformity with industrial safety regulations

The equipment corresponds to the requirements of industrial safety regulations and rules valid and can be applied at explosive and flammable chemically hazardous enterprises and facilities, including mines with explosive proof, coal dust and methane access. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA product portfolio includes various models of SuspendMag М magnetic iron separators, which can be applied over conveyor belts with width from 500 to 1 600 mm. Customized solutions can be designed according to the order requirements.

| Model | Belt width, mm | Removal area depth *, mm | Belt speed, m/s | Machine weight, kg |

|---|---|---|---|---|

| SuspendMag М 500 | 500 | 250 | 1,5 | 370 |

| SuspendMag М 650 | 650 | 250 | 1,5 | 500 |

| SuspendMag М 800 | 800 | 300 | 2 | 650 |

| SuspendMag М 1000 | 1000 | 300 | 2 | 950 |

| SuspendMag М 1200 | 1200 | 300 | 2 | 1100 |

| SuspendMag М М 650 | 650 | 300 | 2 | 600 |

| SuspendMag М М 800 | 800 | 350 | 2 | 1000 |

| SuspendMag М М 1000 | 1000 | 350 | 2 | 1200 |

| SuspendMag М М 1200 | 1200 | 350 | 2 | 1350 |

| SuspendMag М P 800 | 800 | 400 | 3 | 1500 |

| SuspendMag М P 1000 | 1000 | 400 | 3 | 1800 |

| SuspendMag М P 1200 | 1200 | 450 | 3 | 2000 |

| SuspendMag М P 1400 | 1400 | 450 | 3 | 2600 |

| SuspendMag М P 1600 | 1600 | 450 | 3 | 3000 |