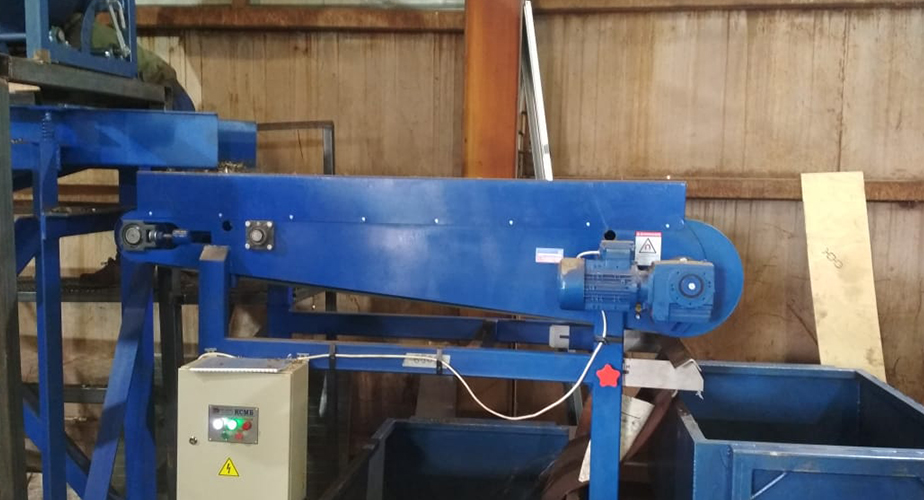

Conveyor magnetic separator ERGA PullMag C

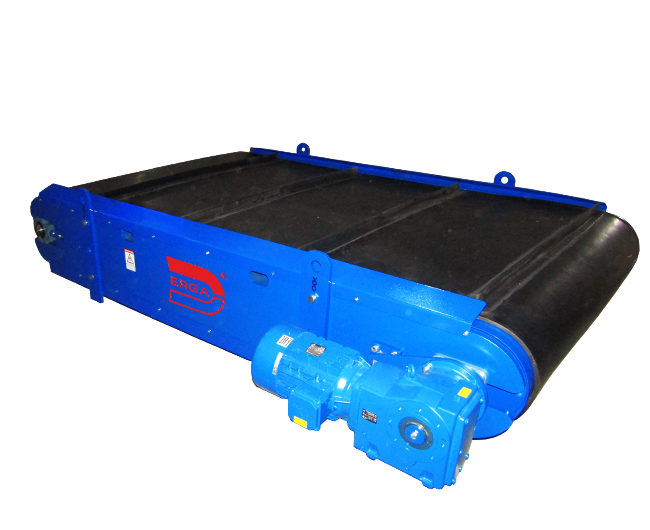

Belt conveyor equipped with magnetic drive pulley for continuous removal of strongly magnetic inclusions of various sizes from bulk flow

-

Integrated solution

-

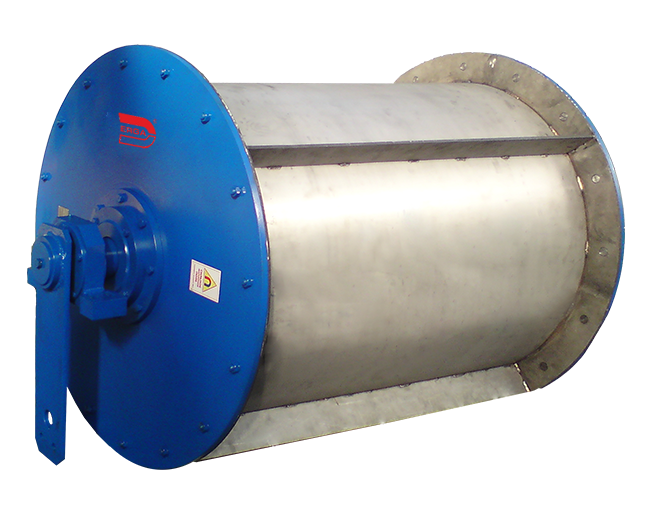

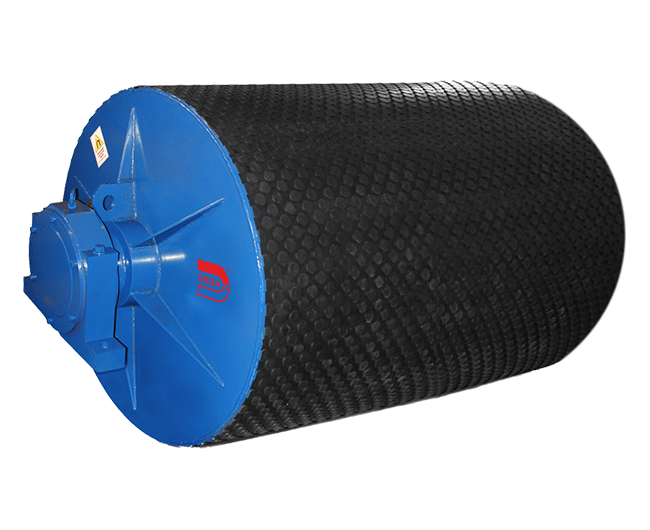

Powerful permanent magnetic system

-

Recovery of inclusions with size up to 350 mm

-

High energy efficiency

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

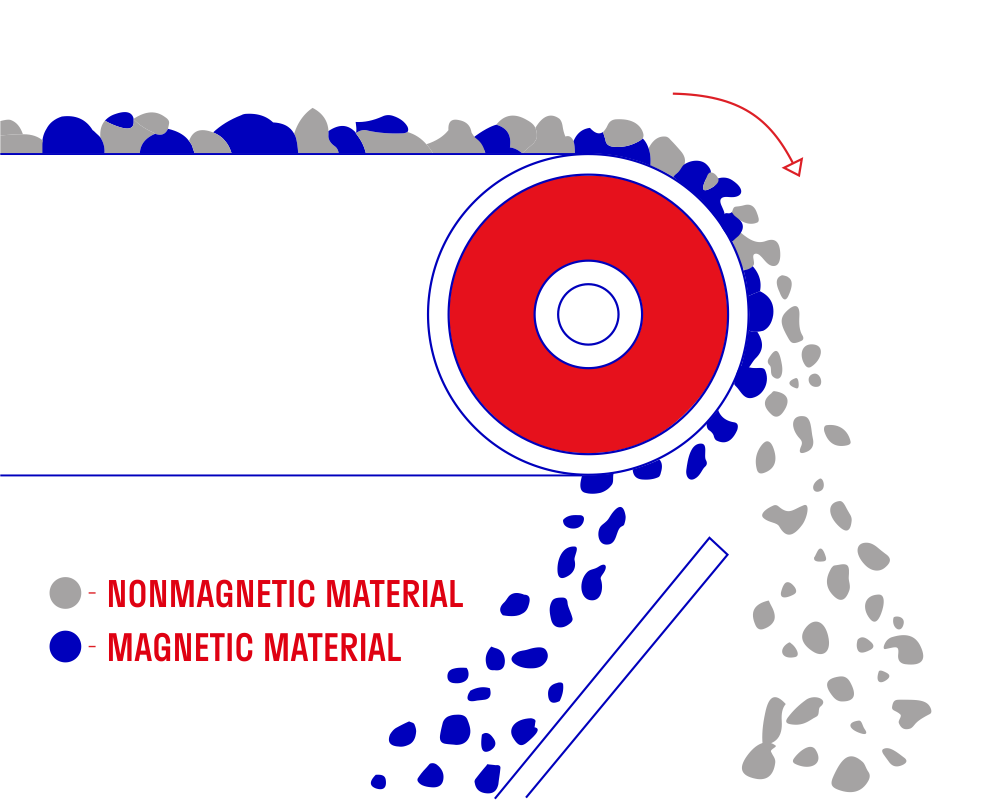

Operation Principle

Industries

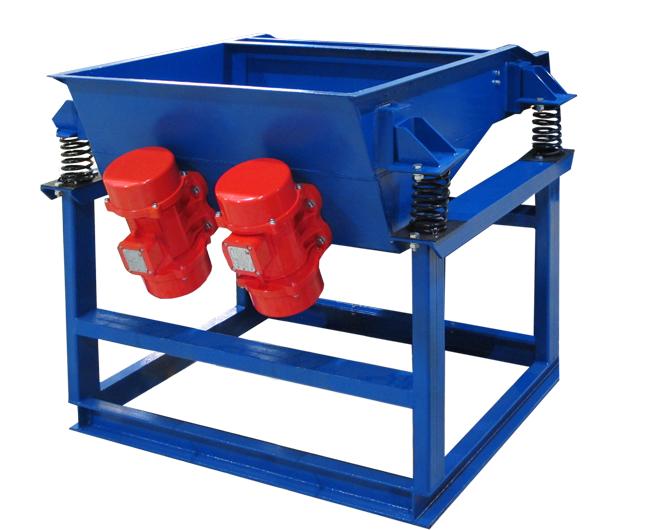

Conveyor magnetic iron separator ERGA PullMag C equipped with magnetic drive pulley ensures continuous high-quality recovery of coarse and medium strongly magnetic inclusions from the flow of bulk raw materials.

- Integrated solution

Ready solution, which can easily be integrated into process line with minimum reworks.

- Powerful permanent magnetic system

Powerful permanent magnetic system provides reliable holding of magnetic inclusions and long-range magnetic field required for recovery of inclusions with size up to 350mm.

- High energy efficiency

Minimum power consumption required only for the conveyor drive and absolutely no consumption for magnetic field generation contribute to significant energy savings.

Guaranteed operation life of magnetic system, subject to operating rules, is 10 years.

- Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic without operator’s involvement.

- Operation temperature range from -50°С to +50°С

Reliable magnetic system and simple design of the separator ensure its operability in a wide temperature range from -50°С to +50°С.

PullMag C provides efficient operation in any weather conditions, indoors and outdoors.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.