Products

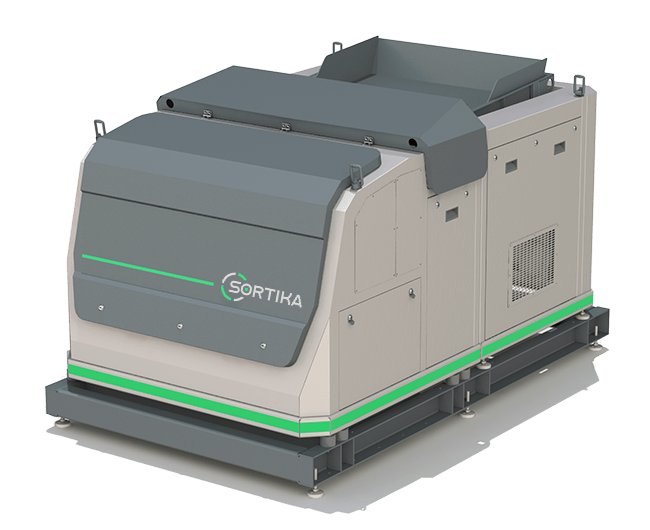

Air separator Resoline Air Flow

-

Separation/cleaning efficiency up to 98%

-

Adjustable separation parameters

-

High throughput

-

Low power consumption

Air separation complex Resoline Air Flow for RDF preparation

-

Industry: recycling

-

Raw material: municipal solid waste

-

Size of feed material: up to 150 mm

-

Throughput: up to 20 t/h

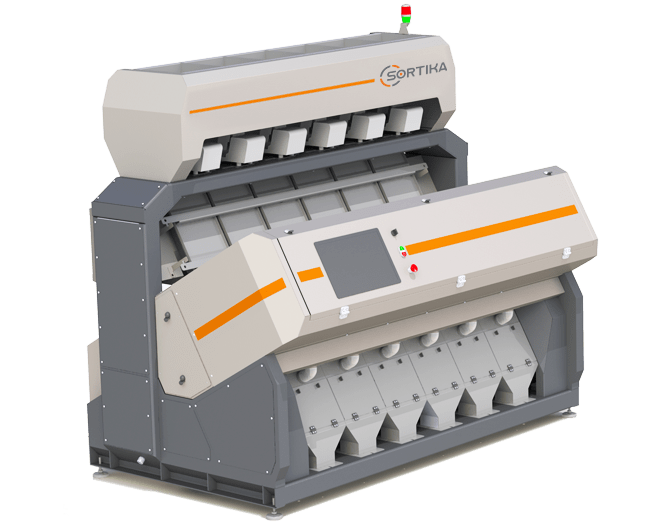

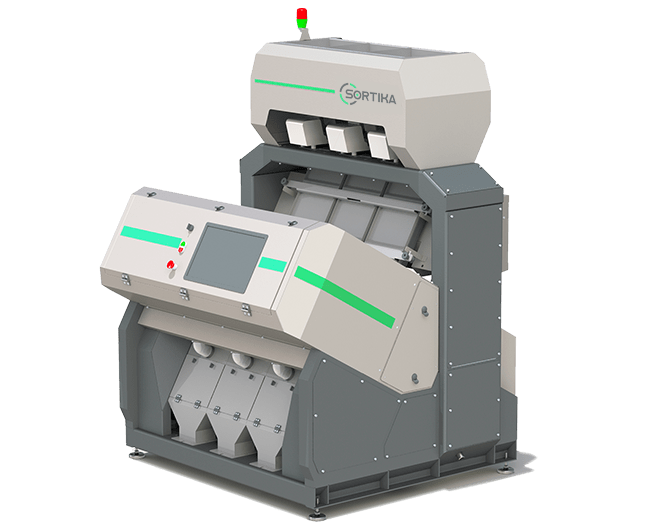

Optical separator Lux Sortika VF

-

Separation efficiency up to 99,99%

-

Operation with difficult abrasive materials

-

User-friendly and fast setup

-

Two stages of separation in one housing

Resoline ferrous scrap cleaning line

-

Industry: ferrous metallurgy, recycling

-

Raw material: ferrous scrap

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline crushing and screening complex for processing of steel slag

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline incineration bottom ash recycling line

-

Industry: MSW treatment

-

Raw material: bottom ash from MSW incineration plant

-

Size of feed material: 0-100 mm

-

Capacity: 15 t/h

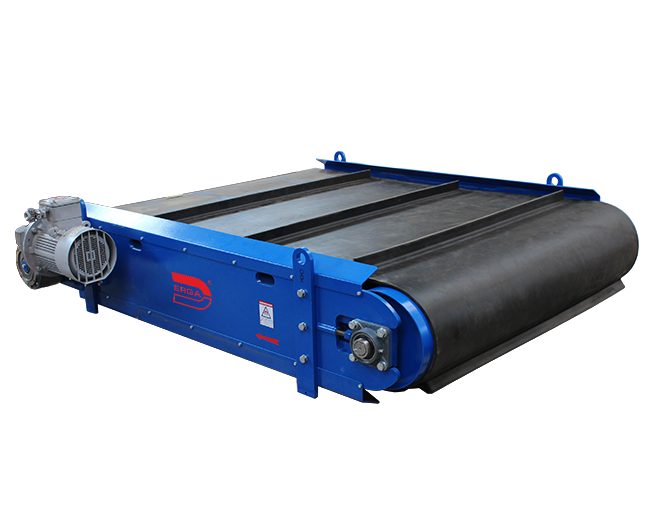

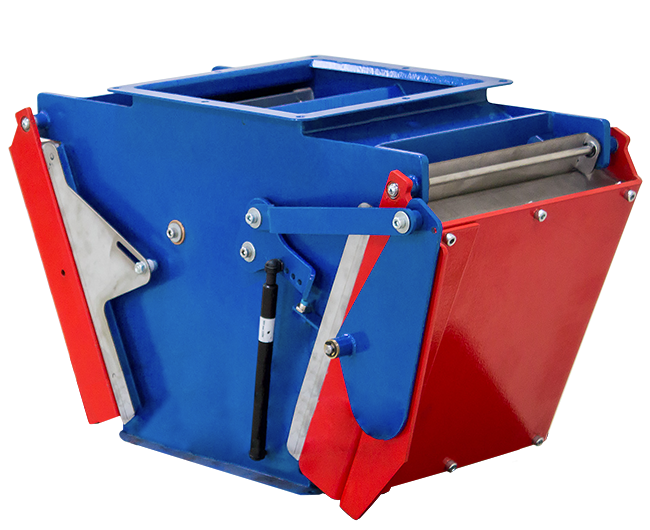

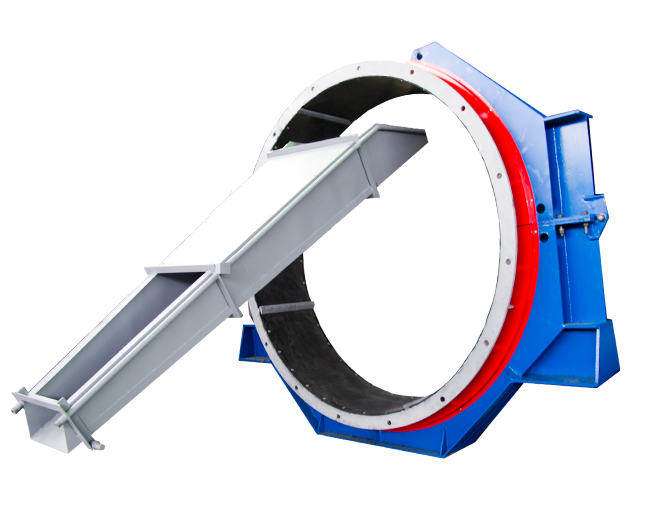

Overbelt self-cleaning magnetic separator for MSW ERGA SuspendMag A

-

Increased length of permanent magnetic system

-

Efficient throw of magnetic fraction outside conveyor

-

Removal area depth up to 350 mm

-

Mass of recovered metal up to 30 kg

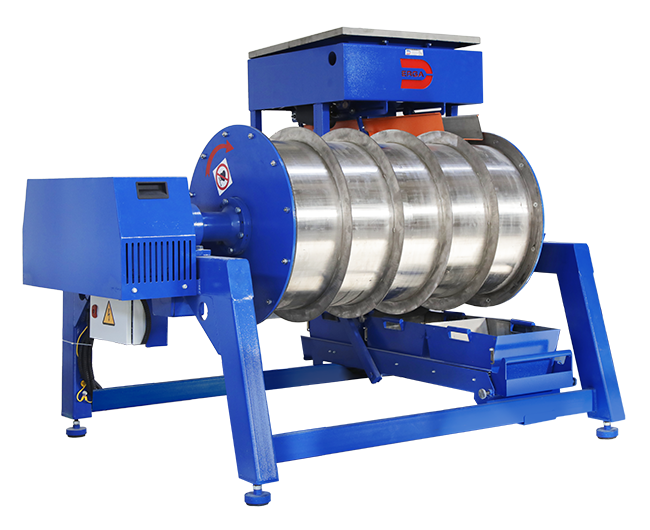

Eddy current magnetic separator for MSW sorting ERGA EddyFlow VF

-

Recovery of nonferrous metal particles from 2 mm

-

Highly efficient NdFeB magnetic system

-

User-friendly and fast setup

-

Material feed via a vibrating feeder

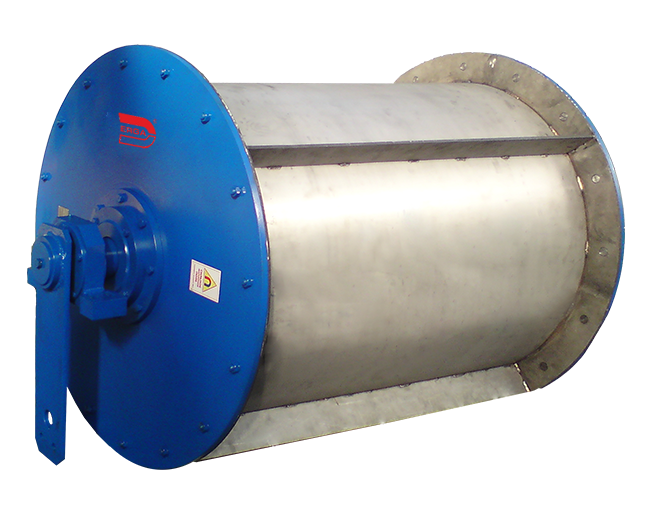

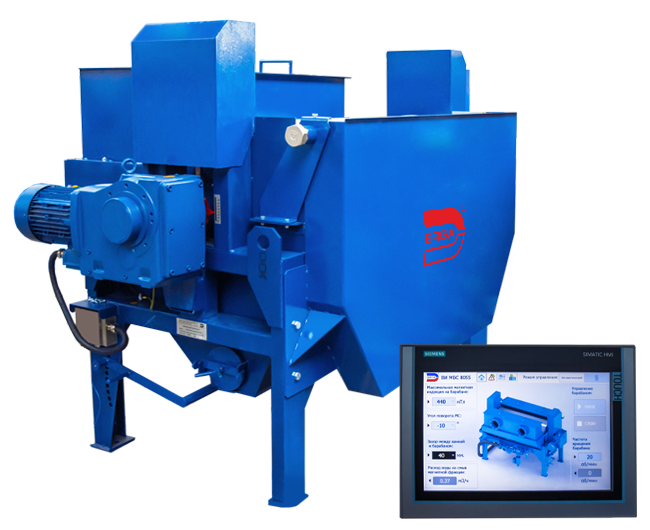

Magnetic drum separator ERGA DrumMag

-

Permanent magnetic system with intensity from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

-

Automatic cleaning

-

Operation temperature range from -50°С to +50°С

Automatic magnetic plate separator ERGA PlateMag A

-

Production automation

-

Highly efficient magnetic system with magnetic intensity up to 0.9 T (9 000 Gauss)

-

Product cleaning efficiency up to 99%

-

Reliable retention of fines

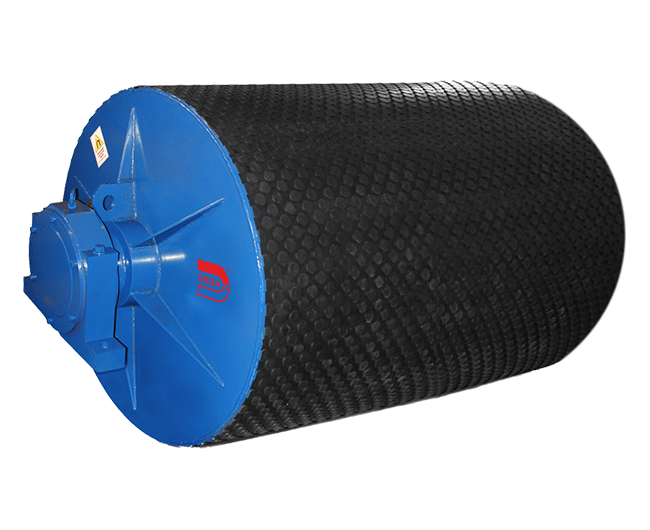

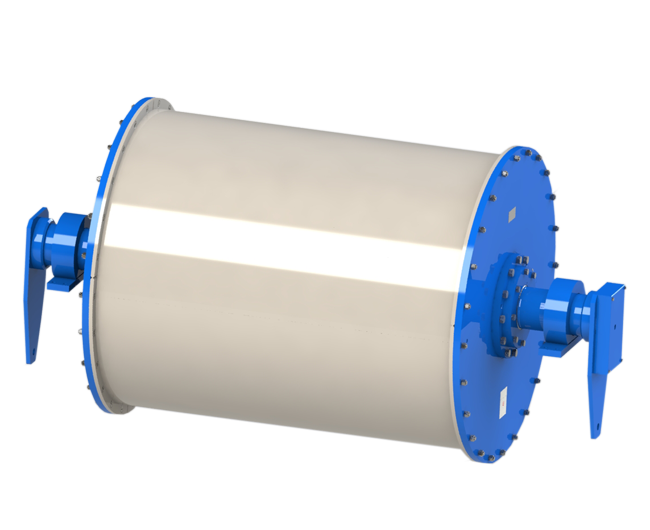

Magnetic pulley ERGA PullMag

-

2 in 1: magnetic iron separator + head pulley

-

Magnetic field operation range up to 350 mm

-

No power consumption

-

Automatic cleaning

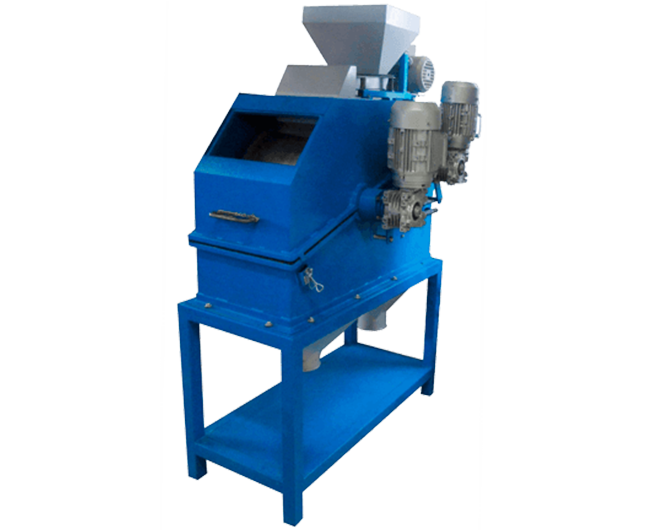

ERGA ELKRON ESS electrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

High capacity

-

User-friendly and fast setup

-

Automatic cleaning of electrodes

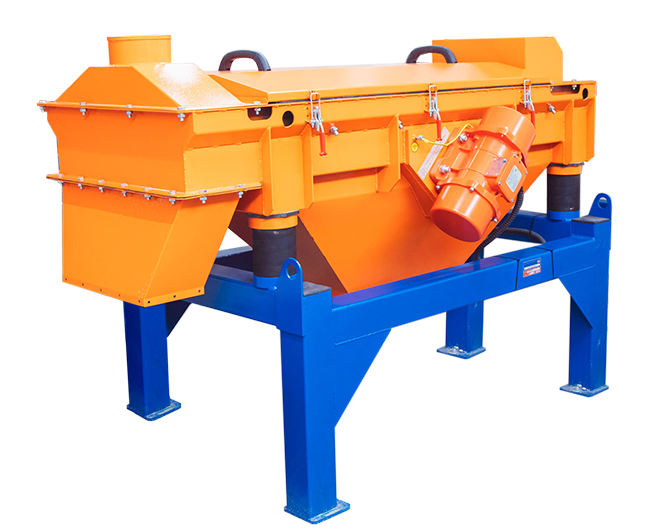

Air separator (pneumatic separator) ERGA ZZFlow

-

Separation/cleaning efficiency up to 99%

-

High throughput

-

Adjustable separation parameters

-

Low power consumption

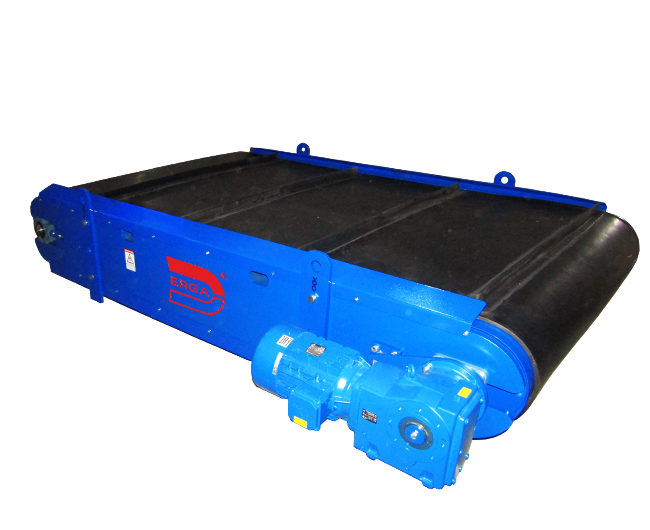

Overbelt self-cleaning magnetic separator ERGA SuspendMag A

-

Efficient operation in harsh conditions

-

Removal area depth up to 550 mm

-

Mass of recovered metal up to 60 kg

-

Powerful permanent magnetic system

Optical separator Glas Sortika

-

Obtaining first grade glass scrap

-

24/7 continuous operation

-

Easy and fast customization

-

Two separation stages in a single housing

Resoline nonferrous scrap recycling line

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 5 t/h

Resoline aluminum slag recycling line

-

Industry: nonferrous metallurgy, recycling

-

Raw material: aluminum slag

-

Size of feed material: 2-40 mm

-

Capacity: 5 t/h

Magnetic roll separator ERGA RollMag

-

High quality separation of weakly magnetic minerals

-

Highly efficient NdFeB magnetic system

-

Easy assembly and operation

-

Operating temperatures up to +180°С

Eddy current magnetic separator with digital control ERGA EddyFlow E5

-

Recovery of metal particles from 3 mm

-

Separation/cleaning efficiency up to 99,8%

-

Highly efficient NdFeB magnetic system

-

Touch Screen intuitive control

Magnetic plate separator ERGA PlateMag 3

-

Off-the-shelf solution: iron separator + elevator boot

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

RESOLINE magnetic and electrostatic concentration and separation line

-

Obtaining high-quality concentrates with purity up to 99,8%

-

Compact automatic complex

-

Dry separation process

-

Wide range of options and settings

ERGA ELKRON TESS triboelectrostatic separator

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal and mineral particle size from 0.040 to 8 mm

-

One machine for various mixtures

-

High capacity due to enlarged diameter of collecting electrode

Overbelt magnetic separator ERGA SuspendMag М

-

Efficient recovery of large strongly magnetic impurities

-

Removal area depth up to 450 mm

-

Mass of recovered metal up to 40 kg

-

Easy assembly and operation

Optical separator Lux Sortika CF

-

Efficient separation of minerals less than 10 mm

-

24-7 mineral raw material separation

-

2x productivity increase on the same equipment

-

Up to 3 stages in a single housing

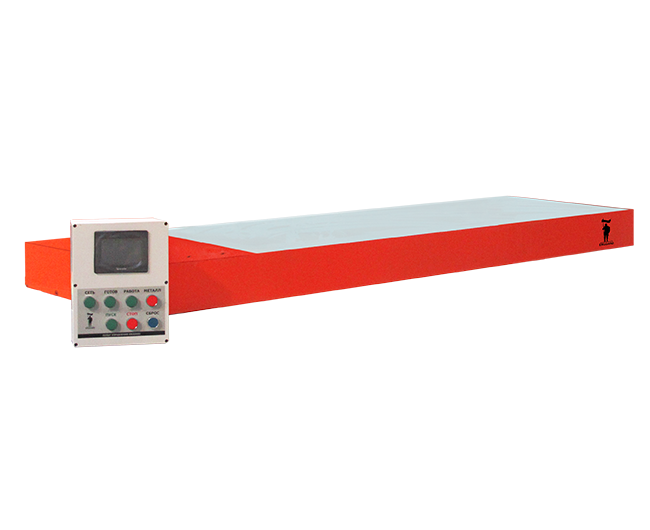

ERGUARD DCM conveyor dismountable metal detector

-

Sectional casing

-

Easy installation

-

High sensitivity to metal inclusions

-

Continuous diagnostics and automatic protection system

Magnetic drum separator ERGA DrumMag M

-

Permanent magnetic system with intensity from 0.08 to 1.0 Т

-

Efficient recovery of magnetic inclusions with size from 150 mm to 0.02 mm

-

Dust protection

-

Availability of all settings necessary for operation

Eddy current magnetic separators ERGA EddyFlow and EddyFlow E

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal particles from 3 mm

-

User-friendly and fast setup

-

Highly efficient NdFeB magnetic system

Magnetic plate separator ERGA PlateMag 2

-

Integrated solution

-

Compact design of the housing

-

Highly efficient NdFeB magnetic system

-

High capacity of cleaning material

Overbelt magnetic separator ERGA SuspendMag P

-

Optimum solution for simple tasks

-

Removal area depth up to 200 mm

-

Easy assembly and operation

-

Easy cleaning

Optical separator Re Sortika CF

-

24-7 mineral raw material separation

-

Dry enrichment technology

-

Operator-free automatic

-

Remote monitoring, continuous diagnostics and customization

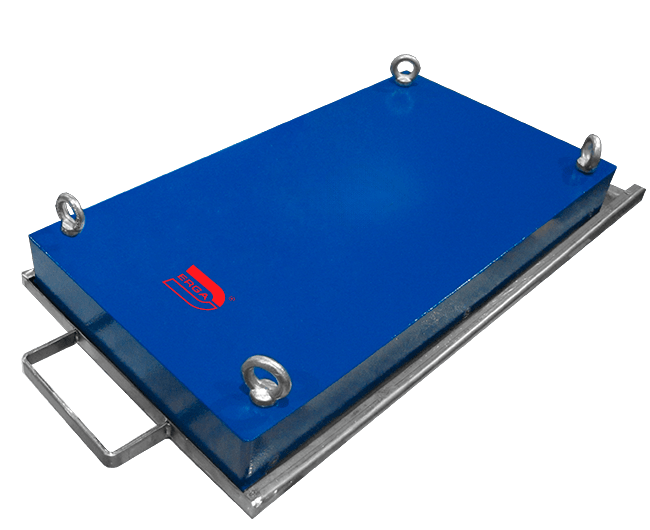

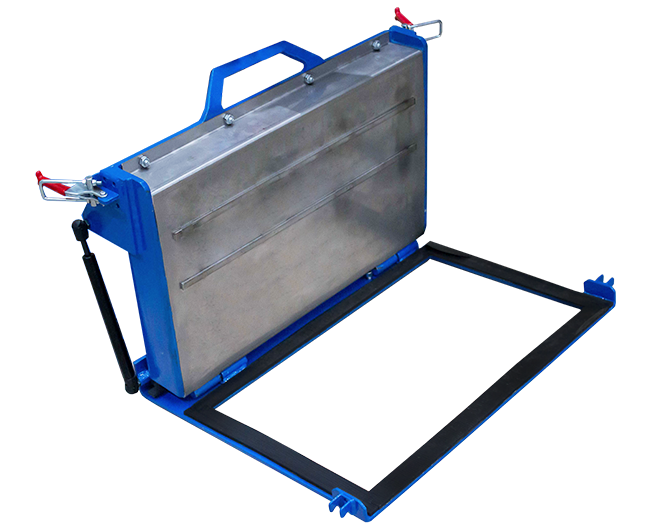

ERGA PSM-VO magnetic bracket

-

Highly efficient NdFeB magnetic system

-

Unique solution for safety of works

-

Easy installation and operation

-

Efficiency x14 times higher*

ERGUARD SCM conveyor single plate metal detector

-

Compact solution

-

High sensitivity to metal inclusions

-

Protection of crusher, shredder from damage and early wear

-

IP rating of product/sensors: IP54/IP65

Magnetic double-drum separator for dusty products ERGA DrumMag DM

-

Minimum losses of fines during separation

-

Pure magnetic fraction

-

Dry separation method

-

Automatic cleaning

Optical separator Lux Sortika BF

-

Efficient separation by mineral composition

-

Preparation of concentrate by dry method

-

Discharge of final tailings

-

Proprietary software with lifetime tech support

Wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with intensity from 0.08 to 0.4 Т

-

Special magnetic system for wet separation process

-

Efficient recovery of magnetic inclusions with size from 0.005 mm to 10 mm

-

Protection of operating surfaces

Magnetic plate separator ERGA PlateMag

-

Integrated solution

-

Highly efficient NdFeB magnetic system

-

Reliable retention of fines

-

Guarantee of end product quality

Optical separator Re Sortika BF

-

Efficient separation by composition

-

Proprietary software with lifetime tech support

-

Setup in 3 clicks

-

Up to 2 stages in a single housing

Wet magnetic drum separator ERGA WetMag R

-

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

-

Permanent magnetic system

-

Special design for efficient recovery

-

Customized selection of equipment

Magnetic plate separator ERGA PlateMag V

-

Integrated solution

-

Rugged design of casing for pressurized operation

-

Special NdFeB magnetic system

-

High capacity of cleaning material

ERGA GS gyratory screen

-

Classification efficiency up to 99%

-

Screen mesh size from 0.2mm

-

5 in 1: simultaneous screening into 5 fractions

-

High throughput

Wet magnetic drum separator ERGA WetMag HI with automated control system

-

Automated adjustment of the permanent magnet system and operation modes

-

Automatic adaptation of separator settings

-

Extremely powerful magnetic system with adjustable intensity from 0.1 to 0.6 T

-

Individual selection of magnetic drum size

Wet magnetic drum separator ERGA WetMag HI

-

Extremely powerful magnetic system with intensity from 0.3 to 0.6 T

-

Individual selection of magnetic drum size

-

Special magnetic system for wet separation process

-

Wet separation method

ERGA TS trommel screen

-

High degree of cleaning

-

Efficient screening into 3 fractions

-

Additional automatic cleaning

-

Easy assembly and operation

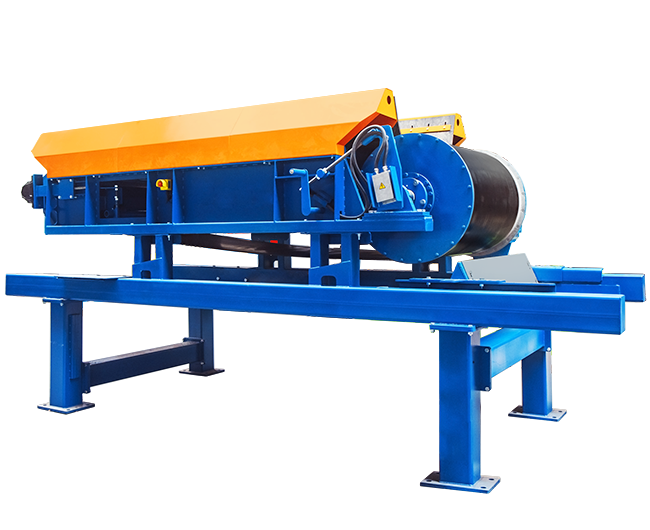

Conveyor magnetic separator ERGA PullMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of inclusions with size up to 350 mm

-

High energy efficiency

ERGA VS vibrating screen

-

Efficient screening into 4 fractions

-

Robust design and high capacity

-

Quick replacement of screens

-

Optional aspiration

Conveyor magnetic separator ERGA DrumMag C

-

Integrated solution

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

ERGA belt conveyors

-

Mobile and stationary conveyors

-

High throughput

-

Bespoke design

-

High class of energy

Magnetic drum separator ERGA DrumMag IC

-

2 in 1: magnetic iron separator + drive pulley

-

Powerful permanent magnetic system

-

Recovery of magnetic inclusions size up to 300 mm

-

Sectoral magnetic system

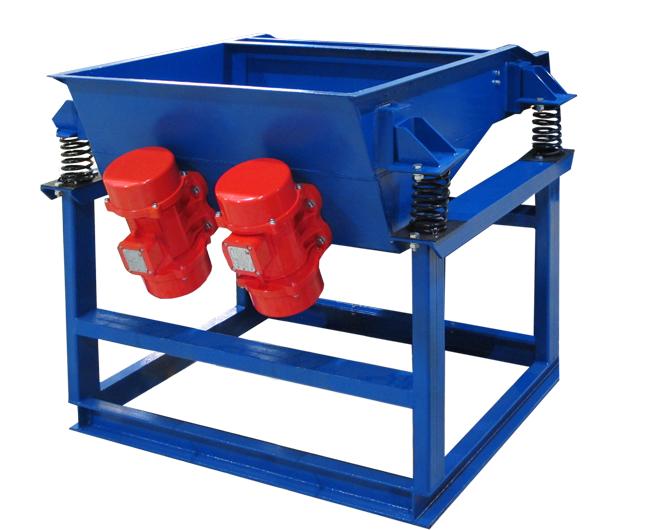

ERGA vibrating feeders

-

Wide range of designs and applications

-

High-strength steel construction

-

Adjustable feed rate and immediate stop

-

Protection of downstream equipment

Scrap trap trunnion magnet ERGA TrunMag

-

Continuous diagnostics and automatic protection system

-

Improvement of ore dressing process

-

Customized solution for various mill sizes

-

Easy installation and operation

ERGA dosing hopper

-

Bespoke design

-

Wide range of options and settings

-

Downtime minimization, no bagging

-

Easy installation and operation

REMOS automated remote monitoring system

-

Monitor equipment condition in real time

-

Remote monitoring and control

-

Minimize downtimes

-

Prevent emergency situation and increase your company operation efficiency

Laboratory electrostatic separator ERGA ELKRON ESS

-

Two stages of separation in one housing

-

Separation/cleaning efficiency up to 99,8%

-

Wide range of separation settings

-

Automatic cleaning of electrodes

Laboratory magnetic drum separator ERGA DrumMag

-

Magnetic system with intensity from 50 to 900 mТ (500 – 9 000 Gauss)

-

Wide range of separation settings

-

Customized selection of equipment

-

Automatic cleaning

Laboratory magnetic drum separator ERGA DrumMag S

-

Wide range of magnetic intensity from 50 to 1 000 mT (500 -10 000 Gauss)

-

Separated material size from 0.1 to 200 mm

-

Automatic cleaning

-

Customized selection of equipment

Laboratory wet magnetic drum separator ERGA WetMag

-

Permanent magnetic system with intensity up to 900 mT (9 000 Gauss)

-

Wide range of separation settings

-

Customized selection of equipment

-

Automatic cleaning

Laboratory magnetic double-drum separator ERGA DrumMag M for dusty products

-

Efficient separation of dusty materials

-

Sealed housing

-

Highly efficient NdFeB magnetic system with intensity up to 900 mT

-

Automatic cleaning

Laboratory dry separation complex ERGA DrumMag-RollMag

-

2 in 1: drum and roll separators in one plant

-

Ideal solution for recovery of rough concentrates

-

Automatic cleaning

-

Customized selection of equipment