Resoline complete process solutions

Air separation complex Resoline Air Flow for RDF preparation

-

Industry: recycling

-

Raw material: municipal solid waste

-

Size of feed material: up to 150 mm

-

Throughput: up to 20 t/h

Resoline ferrous scrap cleaning line

-

Industry: ferrous metallurgy, recycling

-

Raw material: ferrous scrap

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline crushing and screening complex for processing of steel slag

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 10 t/h

Resoline incineration bottom ash recycling line

-

Industry: MSW treatment

-

Raw material: bottom ash from MSW incineration plant

-

Size of feed material: 0-100 mm

-

Capacity: 15 t/h

Resoline nonferrous scrap recycling line

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 5 t/h

Resoline aluminum slag recycling line

-

Industry: nonferrous metallurgy, recycling

-

Raw material: aluminum slag

-

Size of feed material: 2-40 mm

-

Capacity: 5 t/h

RESOLINE magnetic and electrostatic concentration and separation line

-

Obtaining high-quality concentrates with purity up to 99,8%

-

Compact automatic complex

-

Dry separation process

-

Wide range of options and settings

ERGA GS gyratory screen

-

Classification efficiency up to 99%

-

Screen mesh size from 0.2mm

-

5 in 1: simultaneous screening into 5 fractions

-

High throughput

ERGA TS trommel screen

-

High degree of cleaning

-

Efficient screening into 3 fractions

-

Additional automatic cleaning

-

Easy assembly and operation

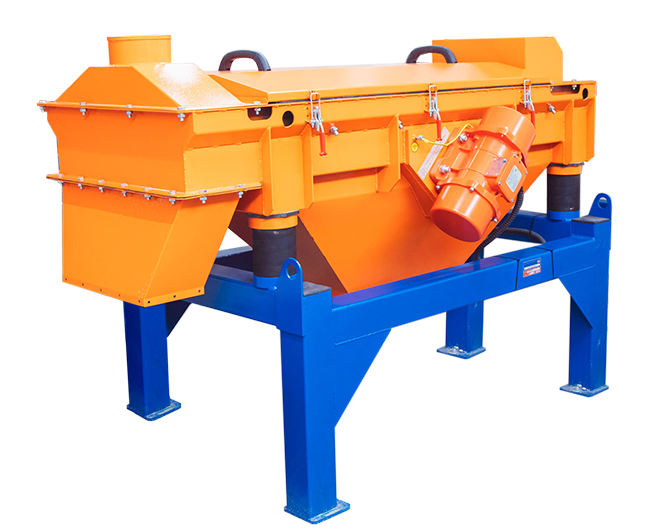

ERGA VS vibrating screen

-

Efficient screening into 4 fractions

-

Robust design and high capacity

-

Quick replacement of screens

-

Optional aspiration

ERGA belt conveyors

-

Mobile and stationary conveyors

-

High throughput

-

Bespoke design

-

High class of energy

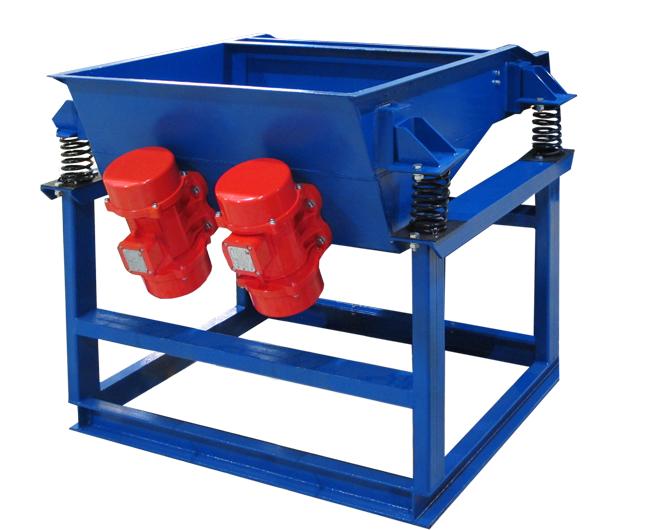

ERGA vibrating feeders

-

Wide range of designs and applications

-

High-strength steel construction

-

Adjustable feed rate and immediate stop

-

Protection of downstream equipment

ERGA dosing hopper

-

Bespoke design

-

Wide range of options and settings

-

Downtime minimization, no bagging

-

Easy installation and operation

REMOS automated remote monitoring system

-

Monitor equipment condition in real time

-

Remote monitoring and control

-

Minimize downtimes

-

Prevent emergency situation and increase your company operation efficiency