Overbelt magnetic separator ERGA SuspendMag P

Budget model of suspended magnetic separator with mechanical cleaing for removal of small metal inclusions from bulk materials

-

Optimum solution for simple tasks

-

Removal area depth up to 200 mm

-

Easy assembly and operation

-

Easy cleaning

-

No power consumption

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

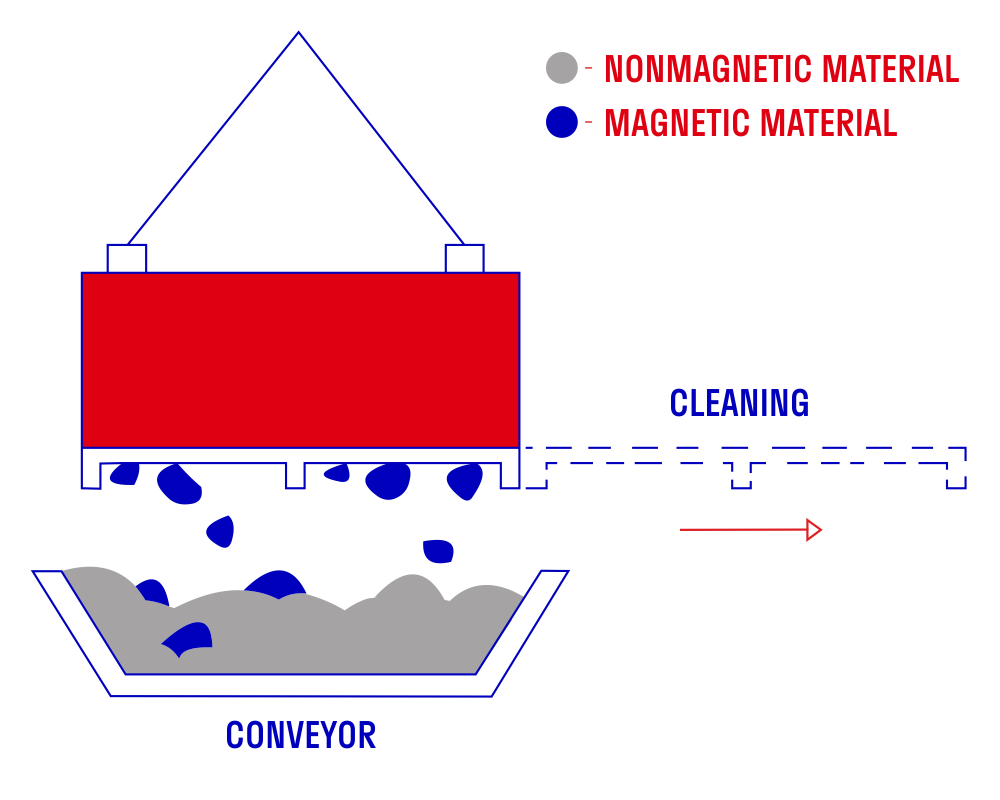

Operation Principle

Industries

ERGA SuspendMag P budget overband magnetic separator with mechanical cleaning ensures qualitative removal of small strongly magnetic inclusions (clips, nails, nuts, etc.) in bulk material from distance up to 200mm.

- Optimum solution for simple tasks

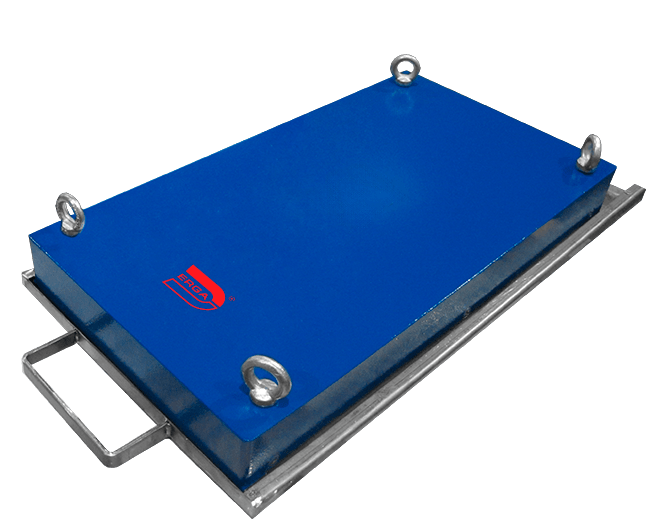

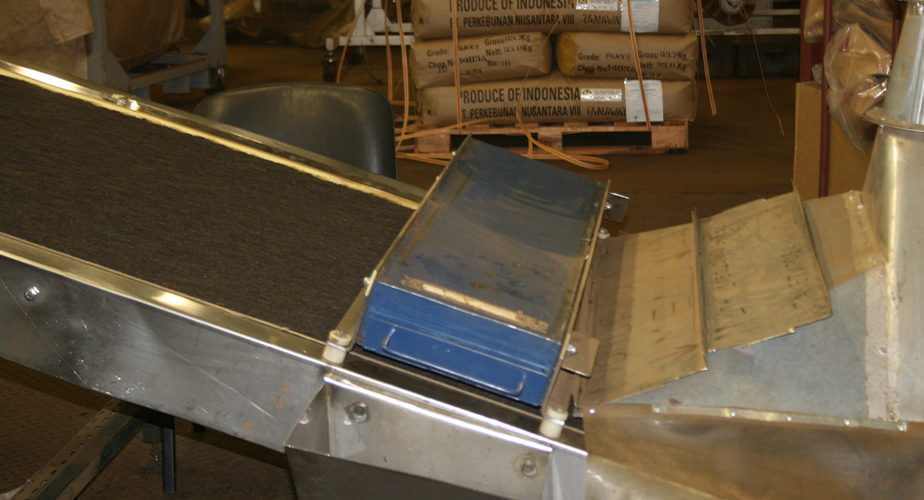

The iron separator is installed over conveyor or at material discharge from the conveyor belt. Simple and robust design of SuspendMag P is a powerful magnetic system installed in protective metal housing with mechanical cleaning system.

- Easy assembly and operation

Compact ERGA SuspendMag P overbelt magnetic iron separator is perfectly integrated into existing process line and does not require any assembly tooling, additional structures for suspension or for redesign of the installation site. There are no bearings or other rotating elements in the iron separator: there is simply nothing to be broken! Proper cleaning from impurities - and no additional maintenance.

- No power consumption

ERGA SuspendMag P magnetic separator does not consume any electric power for magnetic field generation and differs from electromagnetic analogs in significantly greater reliability and efficiency operation for thin layers of material. The guaranteed shelf life of the magnetic system properties, subject to operating rules, is 10 years.

- Easy cleaning

The iron separator has moving rib making mechanical cleaning easier: it is enough to push the rib out of the magnetic field and metal impurities fall off.

- Conformity with industrial safety regulations

The equipment corresponds to the requirements of industrial safety regulations and rules valid and can be applied at explosive and flammable (including vegetable stock storage, processing and utilizing facilities) as well as chemically hazardous enterprises and facilities. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

ERGA product portfolio includes various models of SuspendMag P iron separators with width from 200 to 800 mm. Customized solutions can be designed according to the order requirements.

| Model | Operating area width, mm | Removal depth *, mm | Machine weight, kg |

|---|---|---|---|

| SuspendMag P 200 | 200 | up to 200 | 25 |

| SuspendMag P 300 | 300 | up to 200 | 30 |

| SuspendMag P 400 | 400 | up to 200 | 45 |

| SuspendMag P 500 | 500 | up to 200 | 50 |

| SuspendMag P 600 | 600 | up to 200 | 60 |

| SuspendMag P 800 | 800 | up to 200 | 90 |