Resoline nonferrous scrap recycling line

Line for nonferrous scrap cleaning, sorting from contamination and magnetic inclusions (ferrous metals)

-

Industry: recycling, ferrous metallurgy, nonferrous metallurgy

-

Raw material: shredder residue (ferrous and nonferrous metal scrap)

-

Size of feed material: 0-300 mm

-

Capacity: 5 t/h

-

Fractional composition of end products:

-

Scrap: +300;

-

Screenings: 0-300 mm;

-

Nonferrous metal: 5-300 mm;

-

Ferrous metal: 5-300 mm;

-

Sand, soil: 0-5 mm

-

Nonferrous scrap sorting

-

Obtaining saleable nonferrous scrap

-

Commissioning: september 2015

Industries

Sorting and cleaning of nonferrous metals from contamination and magnetic inclusions at scrap collection and processing stations ensure recovery of material with required quality. Line for cleaning nonferrous scrap from sand, waste, dirt and ferrous metal is a simple and reliable solution for operation automation and reduction in manual sorting costs.

- Problem description:

Nonferrous scrap is an optimum raw material for meeting the industry need in the production of new products. However, the material accepted by the nonferrous metal collection points has excessive contamination. The transportation of nonferrous scrap can also be accompanied by the inclusion of additional components that reduce the quality of raw materials and ultimately affect the price.

Nonferrous scrap recycling reduces the volume of transported raw materials, increases the quality of metal after cleaning and sorting.

Contacting ERGA to solve his problem, the Customer received a simple and reliable solution within the shortest possible time and at optimum cost. Having its own development department, many years of experience in solving similar problems, ERGA integrated the Client's vision into proven solutions used in metal scrap recycling lines. The Customer recouped his investment in the line and started to gain profit in less than 1 year due to high demand for nonferrous metals, low maintenance costs and getting saleable nonferrous scrap.

- Automatic turnkey complex solution

ERGA accomplished a full range of services from design to installation and commissioning of the line for cleaning nonferrous scrap from contaminants according to the Customer’s specifications.

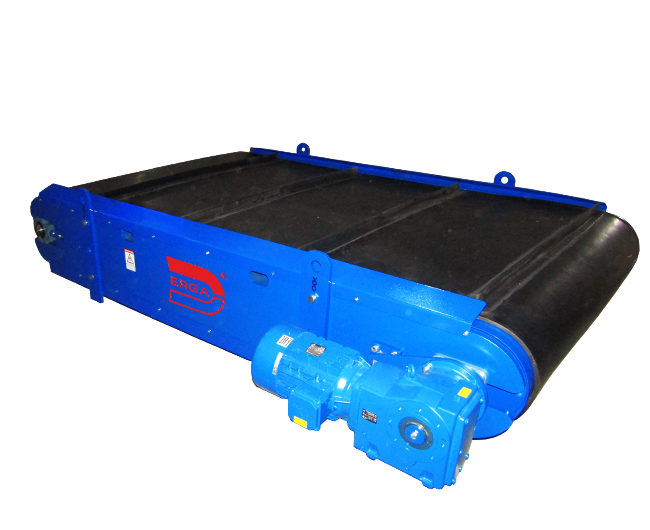

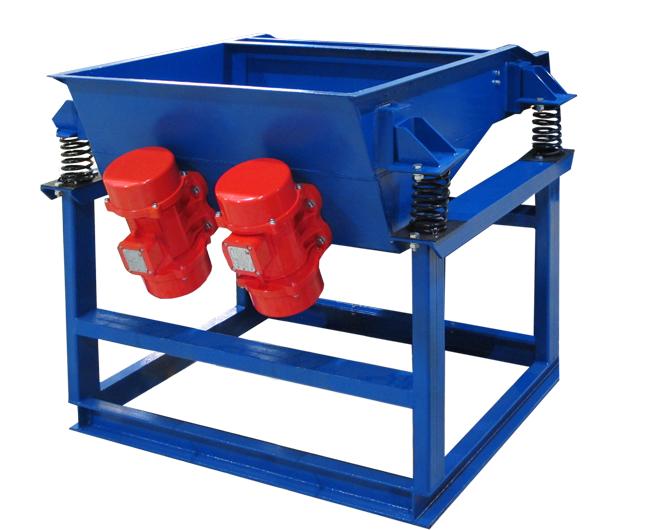

The separators in the line are equipped with automatic cleaning system and provide extraction and removal of scrap contamination. The entire process can be controlled by one operator from the control panel. Monitoring of critical points can be via video conferencing at the operator's site or remotely via Internet.

- Nonferrous scrap recycling

In this project material passes through several stages of magnetic separation with different magnetic field intensities; magnetic inclusions are separated from feed material. Contaminated ferrous scrap is fed into ERGA GB drum screen (trommel), where it is cleaned from sand and dirt. Non-magnetic fraction is conveyed to ERGA EddyFlow eddy current separator, where nonferrous metal is cleaned from nonmetallic inclusions.

- Obtaining saleable nonferrous scrap

Nonferrous metal recycling with cleaning and magnetic separation is a simple and efficient solution for getting material with scrap contamination not more than 5%.

- Operation in harsh conditions

When designing the line, the experience of deliveries for similar tasks was taken into account, because specifics of scrap cleaning work has such certain requirements as robustness, safety factor of assemblies, quick repairs, availability of replaceable linings. As a result, the Customer was satisfied with both the quality of the equipment and the result of scrap cleaning.

- Green and safe technologies

All line components have low power consumption and also help to reduce power consumption in further production of nonferrous metals and other materials, increase recycling rate and return nonferrous metals into production, reduce consumption of natural resources. The equipment is made in compliance with all safety requirements and standards: all the necessary fences, markings, well-thought-out ergonomics for operation and maintenance are ensured. All machines are equipped with emergency shutdown systems.

- Have difficulties choosing or haven’t found what you are looking for?

Contact us in any convenient way and we will find the right solution for you.