Magnetic plate separator ERGA PlateMag V

Plate iron separator with rugged design of casing for removal of metal contaminants from material flows transported by pneumatic conveyors

-

Integrated solution

-

Rugged design of casing for pressurized operation

-

Special NdFeB magnetic system

-

High capacity of cleaning material

-

Reliable retention of fines

-

Easy assembly and operation

-

Maximum temperature of material up to + 160°С

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

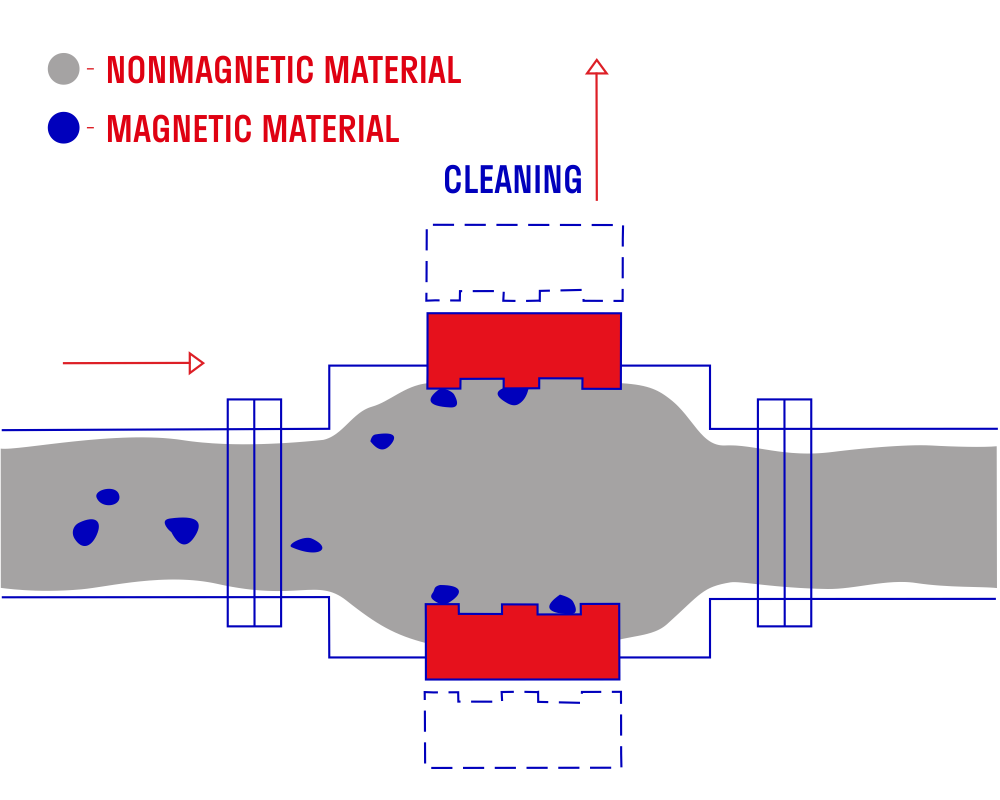

Operation Principle

Industries

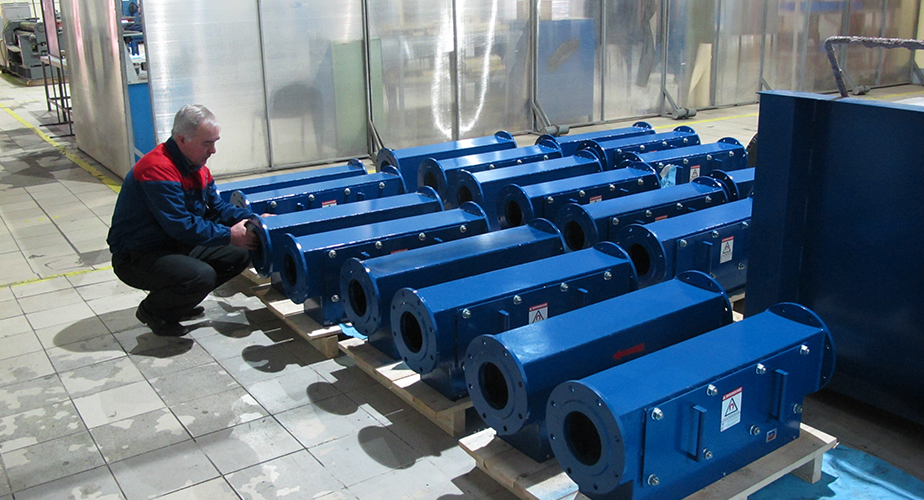

Plate iron separator ERGA PlateMag V with casing designed for pressuried operation is installed in a gravity circular pipeline and ensures efficient cleaning of material transported by pneumatic and vauum conveors, cement pipelines.

- High performance of cleaning material from impurities

Under pressure difference in the pipeline cross section, material enters the magnetic separator, where it is transported between two magnetic plates installed on opposite sides of the gravity pipe. The magnetic system parameters are customized, taking into account peculiarities of the customer’s production, thus guarantee maximum efficient cleaning of material from impurities with high capacity.

Efficient and inexpensive plate iron separators of PlateMag V series are widely used in cement plants, aggregate production plants for construction industry, chemical facilities, as well as flour mills and bakeries.

- Reliable retention of fines

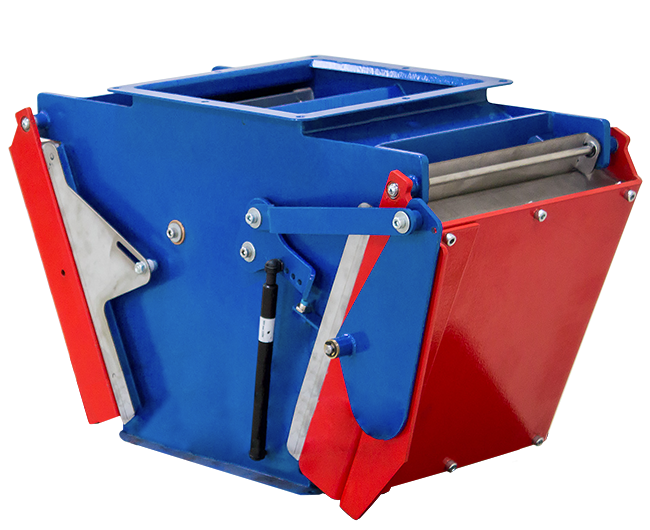

Work surfaces of the magnetic plates are equipped with special ribs forming the so-called shadow zones, necessary for reliable retention of metal fines and preventing their flow with the rest of material.

- Easy assembly and operation

The product design has a proven geometry of the casing, eliminating excessive wear, and all necessary reinforcements to ensure long-term operation.

ERGA PlateMag V iron separators are integrated into the required process line section and does not need any additional redesign. For easy installation backing and fastening flanges are used in PlateMag V design. A spare kit of adapter flanges is available for order.

There are no bearings or other rotating elements in the plate magnetic separator design: there is simply nothing to get broken in it! Proper cleaning of impurities - and no additional maintenance.

- Easy cleaning

The retained impurities are cleaned manually after stopping the product flow and pressure drop.

- Protection from damage and preliminary wear

Rugged design of PlateMag V casing with a powerful magnetic system inside prevents damage and downtime of expensive equipment with resulting financial losses.

- Conformity with industrial safety regulations

The equipment corresponds to the requirements of industrial safety regulations and rules valid and can be applied at food, explosive (including vegetable stock storage, processing and utilization facilities) and chemically hazardous enterprises and facilities. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced magnetic plate separators ERGA PlateMag V are given in the table. Customized solutions can be designed according to the order requirements. The guaranteed operation life of the magnetic system, subject to operating rules, is 10 years.

| Model | Dimensions (LxWxH), mm | Product operating temperature, °С | Throughput, t/h | Magnetic induction on the working surface, mT | Operating pressure, atm | Weight, kg |

|---|---|---|---|---|---|---|

| PlateMag V ND 150 | 630х355х330 | Up to +160 | 90 | Up to 350 | Up to 6 | 200 |

| PlateMag V ND 219 | 960х420х405 | Up to +160 | 120 | Up to 350 | Up to 6 | 350 |