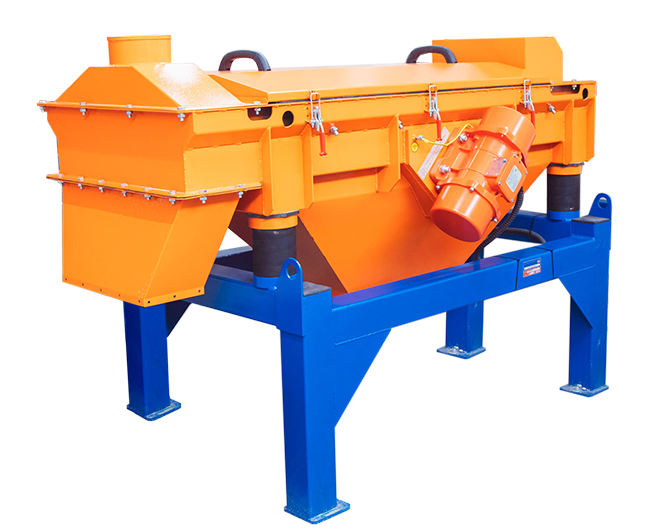

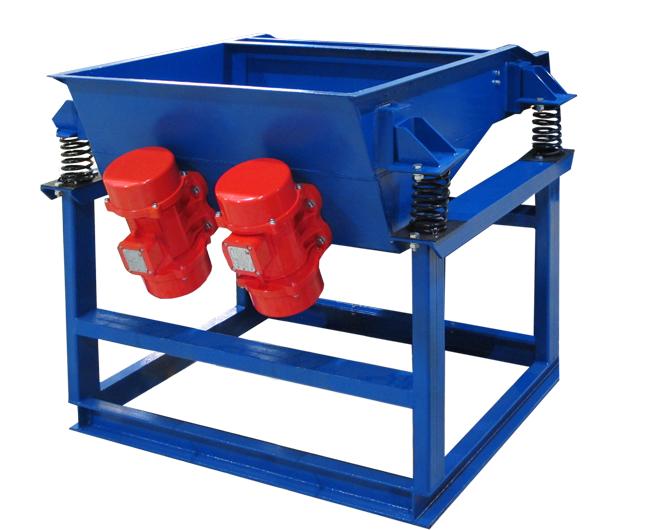

ERGA ELKRON TESS triboelectrostatic separator

Triboelectrostatic drum separator for dry separation of nonconductors with different charge signs

-

Separation/cleaning efficiency up to 99,8%

-

Recovery of metal and mineral particle size from 0.040 to 8 mm

-

One machine for various mixtures

-

High capacity due to enlarged diameter of collecting electrode

-

User-friendly and fast setup

-

Low power consumption (from 0,25 kW)

-

Touch Screen intuitive control

-

Automatic cleaning of electrode

-

Reliable components from the world leaders (Germany, Japan)

-

Integral automatic protection system

-

Dry separation method

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

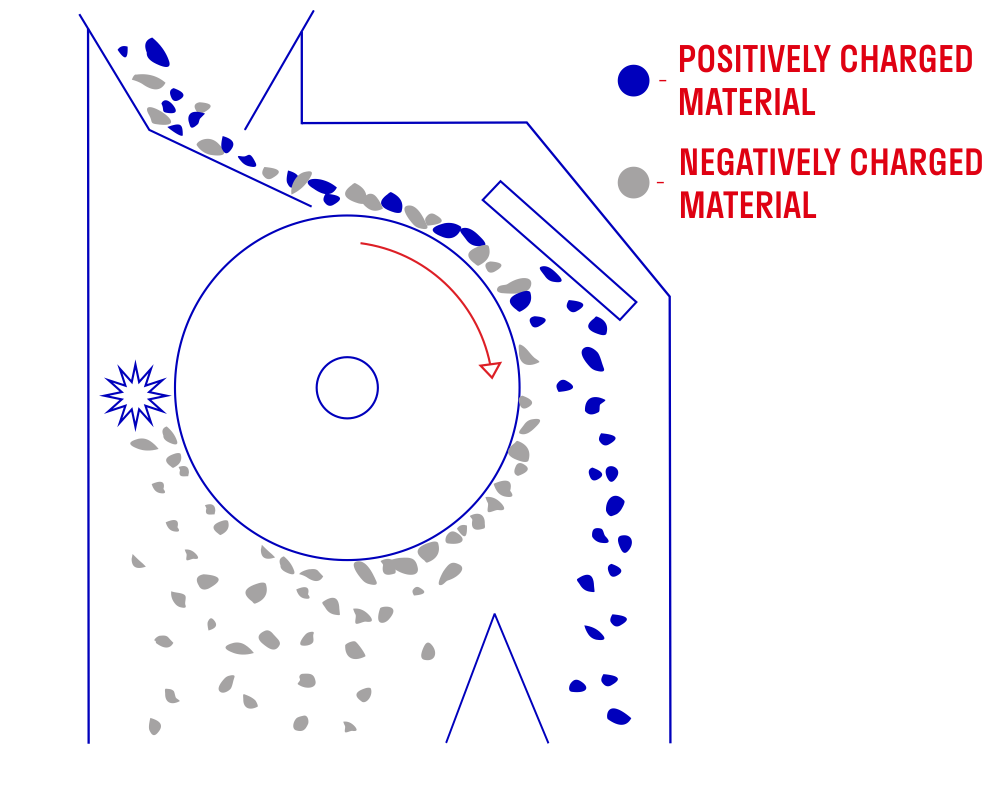

Operation Principle

Industries

ELKRON TESS triboelectrostatic separator provides recovery of the finest metals and mineral particles with size from 0.040 to 8 mm and up to 99.8%. separation and cleaning efficiency of feed material.

- Separation/cleaning efficiency up to 99.8%

Required separation mode is selected depending on feed material. Fine adjustment of the collecting electrode rotation frequency, voltage of the deflecting electrode, position of the splitters ensures up to 99.8% efficiency of separation and cleaning of the feed material.

- One machine for various mixtures

One TESS machine can separate various mixtures of:

– SECONDARY MATERIALS: PET/PVC, ABS/PS, PVC/PVD, PVC /EPDM, PP / PE, etc.;

– MINERAL RAW MATERIALS: quartz - calcite, garnet-hornblende, quartz - feldspar, nepheline - apatite, vermiculite-quartz), etc.

- High capacity

High capacity of ELKRON TESS machine is ensured by the enlarged diameter of collecting electrode (320 mm).

- Touch Screen intuitive control

The control panel is a 7-inch high-definition touch screen with user-friendly interface: 3 levels of access to settings (operator, engineer, service specialist). In addition to settings of main operating parameters of the machine, it is possible to save settings of separation parameters for every type of material.

- Dry separation method: pure economy!

ELKRON TESS triboelectrostatic drum separator allows for replacement or supplement existing equipment, improving material separation quality with less power consumption and no time and money spent on water and drying**.

** comparing to wet separation method

- Automatic cleaning of electrode

Automatic cleaning of collecting electrode allows for downtime elimination.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced models of ERGA ELKRON TESS electrostatic separators are given in the table. Customized solutions can be designed according to the order requirements.

| Model | Roll/drum qty (flows х stages) | Operating area length, mm | Power, kW | Dimenstions (LxWxH),mm |

|---|---|---|---|---|

| TESS-1L 150 | 1 | 150 | 0,25 | 600х515х1100 |

| TESS-1L 300 | 1 | 300 | 1,4 | 1350х1200х1570 |

| TESS-2 600 | 2(1х2) | 600 | 6 | 1100х1100х3200 |

| TESS-2 1000 | 2(1х2) | 1000 | 8 | 1800х1100х3200 |

| TESS-2 1200 | 2(1х2) | 1200 | 8 | 2000х1100х3200 |

| TESS-2 1500 | 2(1х2) | 1500 | 9,5 | 2300х1100х3200 |

| TESS-2 2000 | 2(1х2) | 2000 | 6,3 | 2700х1100х4500 |

| TESS-3 2000 | 3(1х3) | 2000 | 8,5 | 2700х1100х5600 |

| 2TESS-2 2000 | 4(2х2) | 2000 | 12,6 | 2700х2300х4500 |

| 2TESS-3 2000 | 6(2х3) | 2000 | 17 | 2700х2300х5600 |