Eddy current magnetic separator for MSW sorting ERGA EddyFlow VF

Eddy current magnetic separators for recovery of nonferrous metals, Tetra Pak packages from MSW flow

-

Recovery of nonferrous metal particles from 2 mm

-

Highly efficient NdFeB magnetic system

-

User-friendly and fast setup

-

Material feed via a vibrating feeder

-

Conveyor belt width up to 2 000 mm

-

Capacity up to 15 t/h

-

Automatic operation in continuous mode

-

Additional cleaning from ferrous metal tramp

-

Touch Screen intuitive control

-

Easy assembly and operation

-

Fast ROI

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

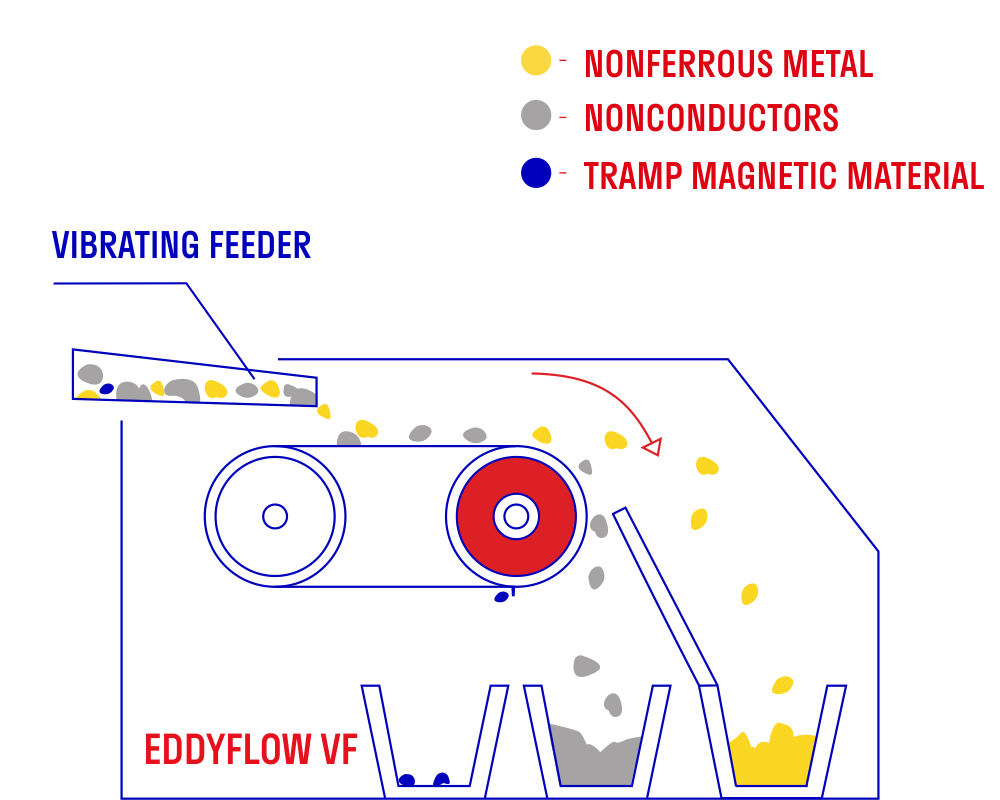

Operation Principle

Industries

Eddy current magnetic separator of special series ERGA EddyFlow VF allows you to increase income from profitable sale of recovered recyclables (nonferrous metals) and reduce costs when sorting solid municipal waste.

- Highly efficient NdFeB magnetic system

Eddy current separator ERGA EddyFlow VF is produced with concentric arrangement of the magnetic rotor relative to the drum axis. The rotor configuration and the number of poles determine the efficiency of removing nonferrous inclusions. Unique patented NdFeB magnetic systems provide long-term efficient operation of magnetic separators. Guaranteed period of magnetic systems properties, subject to operating rules, is 10 years.

- Fine setting of separation mode

Individual separation mode is selected and set according to the requirements for the end products. Precise adjustment of the splitter position, conveyor belt speed up to 3 m/s and magnetic rotor speed up to 3000 rpm allow to achieve efficient separation of the useful fraction of nonferrous metals of various shapes and weights (aluminum cans, Tetra Pak packaging, etc.)

- Material feed via a vibrating feeder

Vibrating feeder ensures even distribution of waste along the entire conveyor belt width (up to 2 000 mm). Material is fed as a monolayer for efficient recovery of the useful fraction containing nonferrous metals. Smooth adjustment of the feed rate of materials is possible with a frequency converter that regulates vibrators' revolutions. The vibration amplitude of the vibrators can be changed by changing the eccentric weight angle position.

- Additional cleaning from ferrous metal tramp

The design feature of EddyFlow VF special series eddy-current separator for MSW provides removal of ferrous metal tramp remaining in the flow after the preliminary stage of separation.

- Advanced control system

The separator can be digitally controlled from the Touch Screen with user-friendly interface. In addition to settings of main operating parameters of the separator, it is possible to save settings of separation parameters for every type of material.

- Easy assembly and operation

Smart design provides quick belt change, protects the magnetic rotor from tramp metal under the belt. Simple design of bearing assemblies increases reliability and also guarantees maintainability of the magnetic rotor, which reduces equipment downtime.

- Fast ROI

Profit from the sale of recovered recyclables guarantees a quick return on investment in installation of the eddy current separator, which ensures continuous efficient operation in automatic mode.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced ERGA EddyFlow VF eddy current separators are given in the table. Customized solutions can be designed according to the order requirements. Strongly magnetic impurities must be removed from the separation materials by ERGA SuspendMag M or SuspendMag A suspended iron separators, ERGA PullMag pulley iron separators or ERGA DrumMag drum separators prior to eddy current magnetic separators.

| Model | Dimensions, mm | Weight, kg | Power consumption, kW | Capacity, t/h |

|---|---|---|---|---|

| EddyFlow VF 1200 | 5200х2400х1300 | 2700 | 12 | 9 |

| EddyFlow VF 1500 | 5200х2700х1300 | 3000 | 12 | 11 |

| EddyFlow VF 2000 | 5200х3200х1300 | 3700 | 14 | 15 |

You can additionally order spare parts kit to ensure continuous operation of the equipment:

- belt

- bearings

- shell

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the separator status in real time. Available options:

- Splitter, flap position sensor

- Access to complete information about operation of the machine (operation / idle, operating modes, error decoding, position of magnetic rods, cleaning period)

- Power supply sensor

- Monitoring operation of electric motors (in case of variable speed drive)

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor