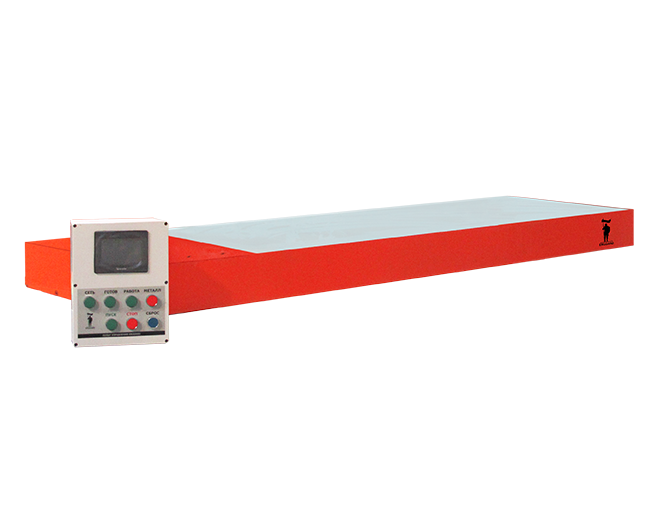

ERGUARD SCM conveyor single plate metal detector

Compact industrial metal detector for detection of tramp metal inclusions in conveyed bulk raw materials

-

Compact solution

-

High sensitivity to metal inclusions

-

Protection of crusher, shredder from damage and early wear

-

IP rating of product/sensors: IP54/IP65

-

Metal sensor control width from 300 to 2 000 mm

-

Conveyor belt speed up to 4m/s

-

High tolerance to vibrations

-

Automatic self-diagnostic system

-

Remote control panel

-

Touch Screen intuitive control

-

Visual and sound alarm

-

Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

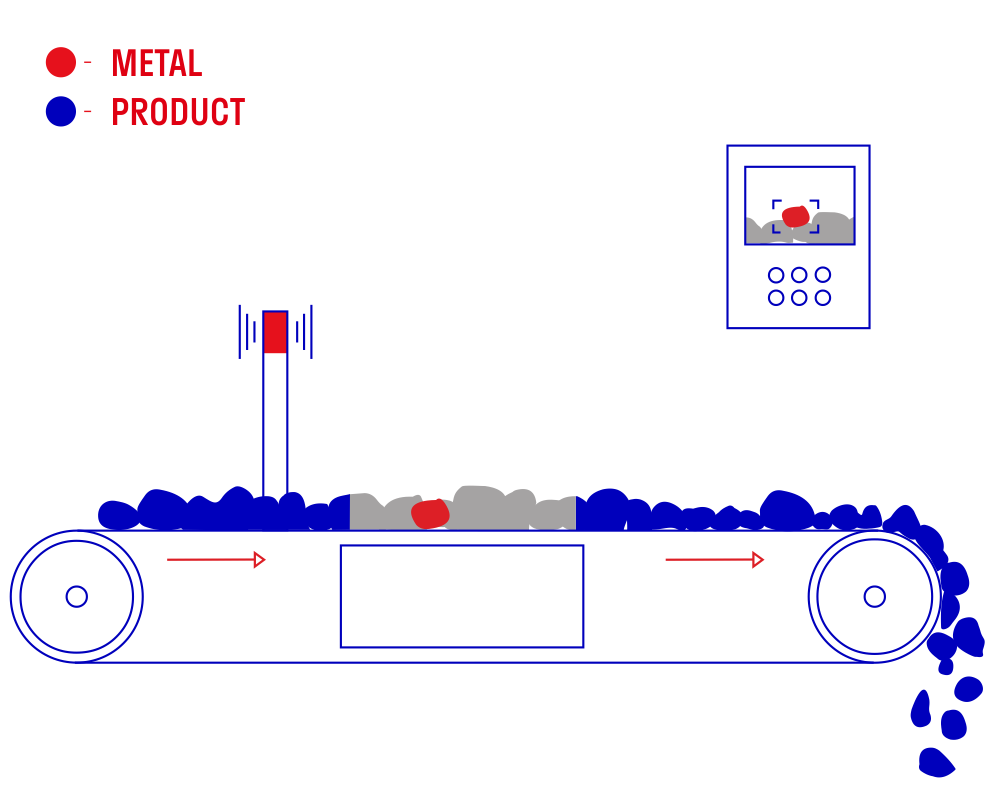

Operation Principle

Industries

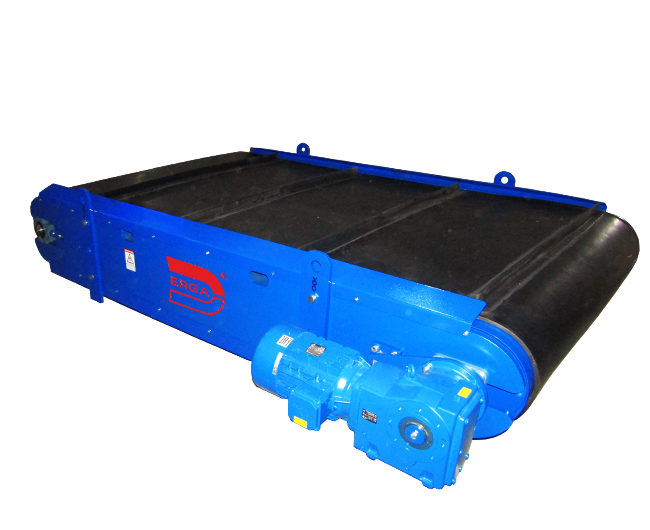

ERGUARD SCM single plate metal detector is designed to detect inclusions of ferrous, nonferrous metals and stainless steel in bulk materials transported by conveyor belt.

- Compact solution

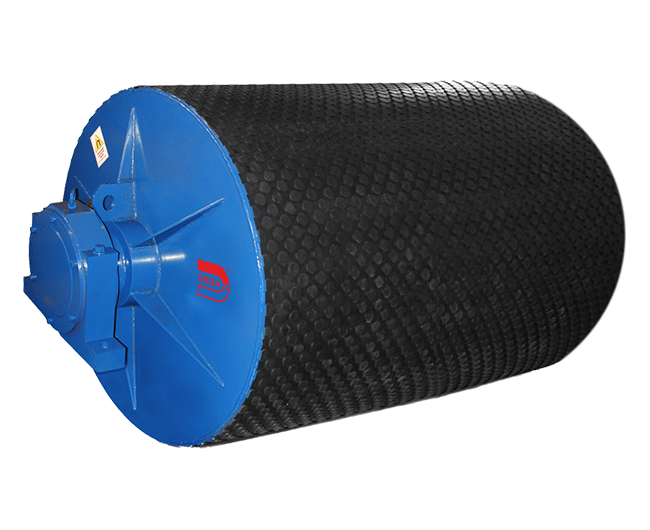

ERGUARD SCM single plate metal detector is easily integrated under conveyor belt without belt disconnection.

- High sensitivity to metal inclusions

ERGUARD SCM single plate metal detector provides maximum sensitivity in detecting inclusions of various sizes.

Sensitivity to ferrous metals:

- from 10 mm at height of 100 mm from the detector plate

- from 20 mm at height of 200 mm from the detector plate

- from 30 mm at height of 300 mm from the detector plate

Sensitivity to nonferrous metals:

- from 20 mm at height of 100 mm from the detector plate

- from 40 mm at height of 200 mm from the detector plate

- from 60 mm at height of 300 mm from the detector plate

The above values are obtained under ideal conditions and can vary depending on the size of the aperture, detector operating frequency, unique properties of the products, location of inclusions in the flow and conditions of the process environment.

- Continuous control

When metal inclusions are detected, the metal detector emits a sound / light signal and depending on selected option stops the conveyor, labels or rejects the contaminated product from the conveyor belt.

The sensor has ambient class NF1 design (ambient temperature - 35 / + 40 °С), which allows working in outdoors in any weather conditions.

- Protection of process equipment from damage and premature wear

ERGUARD SCM conveyor metal detector reduces wear, prevents damage and downtime of crushing and size reduction equipment and eliminates resulting financial losses.

- Touch Screen intuitive control

The control panel is a 7-inch high-definition touch screen with user-friendly interface: 3 levels of access to settings (operator, engineer, service specialist) are provided to prevent unauthorized access.

- Storing up to 10 materials in memory

Individual settings for specific material/product are stored in the system memory, designed for 10 items.

- Conformity with technical regulations of the Customs Union

The equipment corresponds to requirements of technical regulations of the Customs Union TR CU 004/2011 “On Safety of low-voltage equipment” and TR CU 020/2011 “Electromagnetic compatibility of technical equipment”. All required certificates are included in the scope of supply.

- Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.

Series-produced models of ERGUARD SCM conveyor metal detectors are given in the table. Tailored solutions can be designed according to the order requirements.

| Model | Dimensions (LхWхH), mm | Max. power consumption, W | Weight, kg |

|---|---|---|---|

| ERGUARD SCM 500 | 860х550х180 | 150 | 60 |

| ERGUARD SCM 650 | 1010х550х180 | 150 | 70 |

| ERGUARD SCM 800 | 1160х550х180 | 150 | 80 |

| ERGUARD SCM 1000 | 1360х550х180 | 150 | 90 |

| ERGUARD SCM 1200 | 1560х550х180 | 150 | 100 |

| ERGUARD SCM 1400 | 1760х550х180 | 150 | 110 |

| ERGUARD SCM 1600 | 1960х550х180 | 150 | 120 |

| ERGUARD SCM 1800 | 2160х550х180 | 150 | 130 |

| ERGUARD SCM 2000 | 2360х550х180 | 150 | 140 |

For this type of equipment there is an option of integrating REMOS remote monitoring system, providing monitoring of the metal detector status in real time. Available options:

- Access to complete information about operation of the machine (operation / idle, operating modes, error decoding, position of magnetic rods, cleaning period)

- Power supply sensor

- Incoming switch and contactors position control sensor

- Equipment downtime monitoring

- Door status control (open / closed)

- Shock / vibration sensor

- Humidity sensor

- Temperature sensor